How Coaxial Heat Exchangers Work: Step-by-Step Guide

Introduction

Coaxial heat exchangers are key to efficient thermal management. They play a vital role in HVAC, refrigeration, and renewable energy. Since 2005, SHENSHI Energy Conservation Technology has led the way. We offer innovative solutions at https://en.shenshiec.com/. This guide explains how these devices work. It provides a clear, step-by-step breakdown. Our expertise ensures you get reliable insights. Let’s dive into the process.

What is a Coaxial Heat Exchanger?

Definition and Design

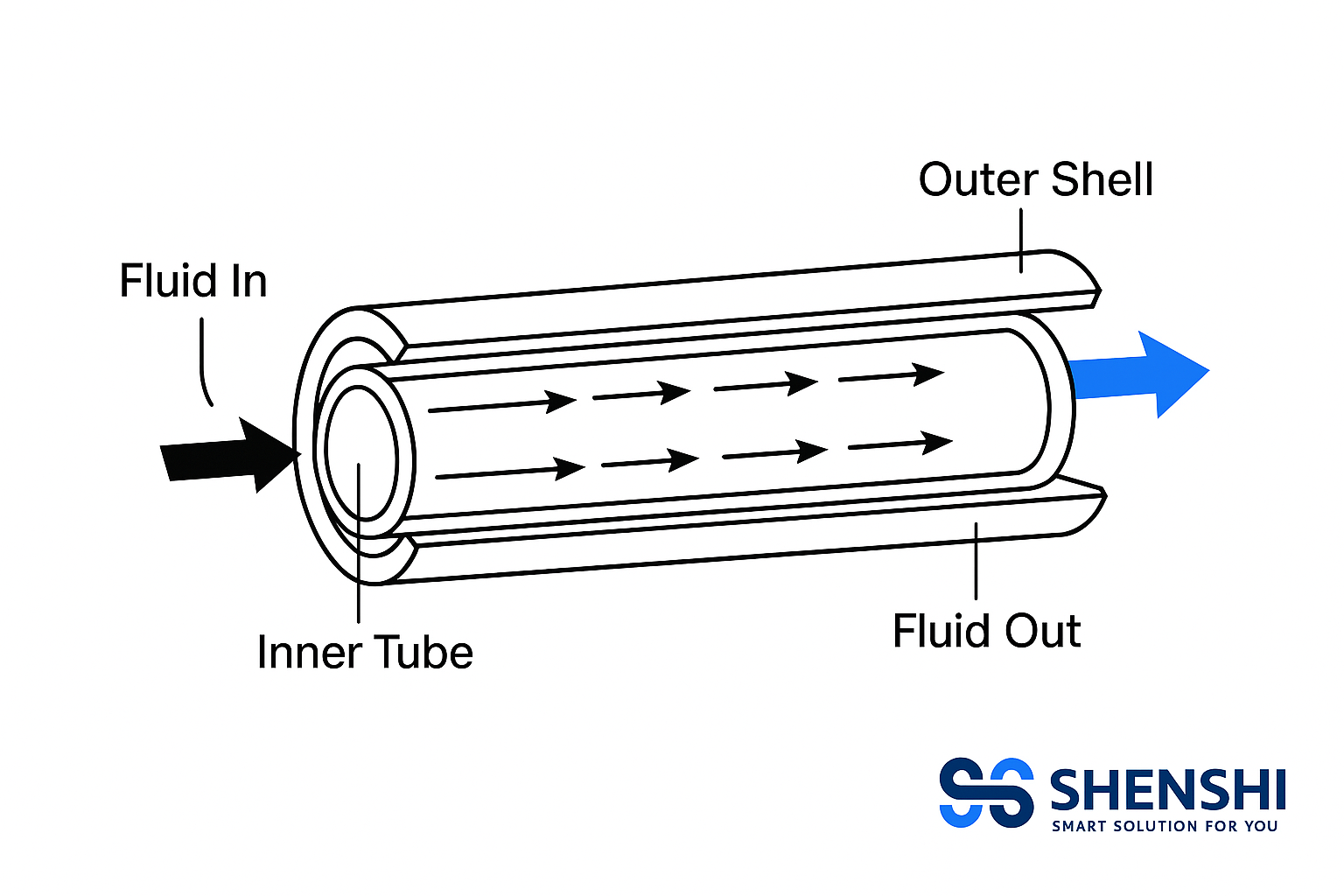

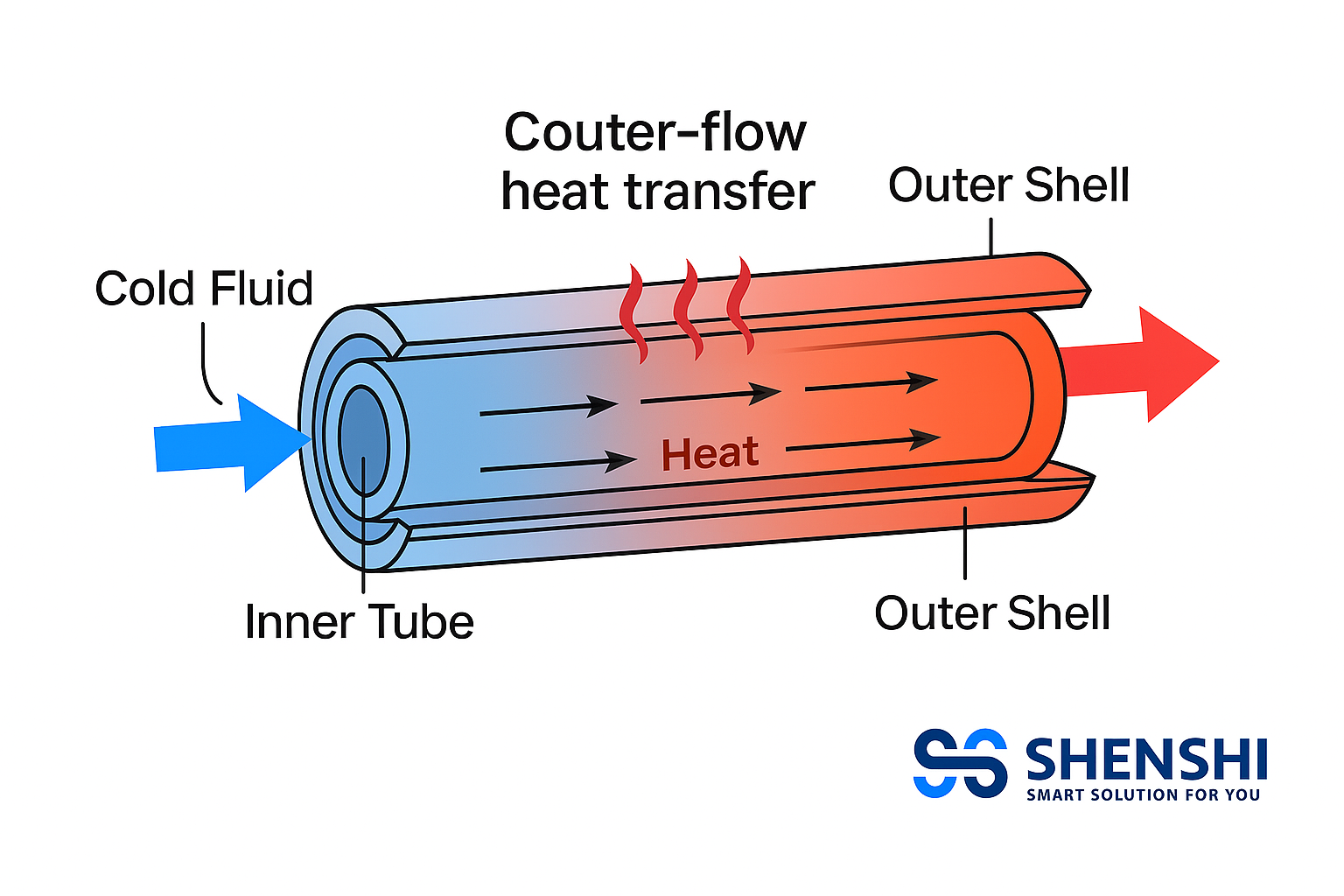

A coaxial heat exchanger uses a "tube-in-tube" structure. One tube sits inside another. This design allows two fluids to exchange heat. The counter-flow system boosts efficiency. SHENSHI designs reflect this principle. They serve industries worldwide.

Key Components

- Inner Tube: Carries one fluid, often water.

- Outer Shell: Houses the second fluid, like refrigerant.

- Grooved Design: Enhances heat transfer area.

Materials Used

SHENSHI uses durable materials. Options include copper and stainless steel. These ensure long-lasting performance. They suit applications from food processing to aerospace.

How Coaxial Heat Exchangers Work: Step-by-Step

Step 1: Fluid Entry and Flow Setup

The process starts with fluid entry. Water flows into the inner tube. Refrigerant enters the outer shell. They move in opposite directions. This counter-flow setup is key. SHENSHI optimizes this with spiral grooves. Our 44,000 m² facility supports this innovation.

- SHENSHI Benefit: Grooves increase efficiency in heat pumps.

- Flow Direction: Ensures maximum heat transfer.

Step 2: Heat Transfer Process

Heat transfers between the fluids. The warmer fluid loses heat. The cooler fluid gains it. This happens through the tube wall. Temperature differences drive the exchange. SHENSHI’s textured tubes boost this effect. They support low-carbon goals.

- Mechanism: Counter-current flow maximizes efficiency.

- Application: Ideal for HVAC and green energy.

Step 3: Optimization and Efficiency

Turbulence improves heat exchange. The grooved design prevents scaling. SHENSHI’s R&D ensures top performance. Our patents cover 46 inventions. This suits high-pressure systems like marine applications.

- Innovation: Spiral design enhances turbulence.

- Durability: Resists corrosion and wear.

Step 4: Fluid Exit and System Integration

Fluids exit after exchange. Cooled water leaves the inner tube. Refrigerant exits the shell. They rejoin their cycles. SHENSHI offers customizable designs. They fit HVAC, refrigeration, and more.

- Integration: Seamless in diverse systems.

- Customization: Tailored by our expert team.

Benefits and Applications

Advantages

Coaxial heat exchangers offer unique benefits:

- Compact Size: Saves space in tight setups.

- High Efficiency: Optimizes energy use.

- Low Contamination: Reduces fouling risks.

Wide Applications

These devices serve multiple industries:

- HVAC: Enhances indoor comfort.

- Renewable Energy: Supports geothermal systems.

- Marine: Optimizes cooling in offshore rigs.

SHENSHI aligns with China’s "dual carbon" strategy. Our solutions promote sustainability.

Technical Insights

Factors Affecting Performance

Several factors influence how well these exchangers work:

- Flow Rate: Impacts heat transfer speed.

- Temperature Difference: Drives the exchange process.

- Material Quality: Affects durability.

Comparison with Other Exchangers

| Feature | Coaxial Heat Exchanger | Shell-and-Tube Exchanger |

|---|---|---|

| Design | Tube-in-tube | Tubes in a shell |

| Efficiency | High | Moderate |

| Space | Compact | Larger |

SHENSHI’s coaxial designs outperform in space-constrained applications.

Why Choose SHENSHI?

Company Background

SHENSHI started in 2005. We employ over 500 employess. Our 44,000 m² base drives innovation. Visit https://en.shenshiec.com/ for details.

Our Strengths

- Innovation: 46 invention patents.

- Quality: ISO9001, ASME, and CE certified.

- Global Reach: Supports aerospace to food industries.

Success Stories

Our partners trust our technology. We’ve delivered solutions for offshore platforms. Explore our cases online.

Maintenance and Troubleshooting

Maintenance Tips

- Regular Cleaning: Prevents scaling.

- Inspection: Check for leaks monthly.

- Professional Service: Contact SHENSHI for support.

Common Issues

- Fouling: Reduced efficiency.

- Leaks: Indicates wear.

- Solutions: Use SHENSHI’s durable materials.

Our global service network ensures quick assistance.

Future Trends

Emerging Technologies

Smart controls enhance performance. New materials improve durability. SHENSHI leads these advancements.

Sustainability Focus

We support carbon neutrality. Our microchannel tech reduces energy use. This aligns with global green goals.

Conclusion

Understanding how coaxial heat exchangers work unlocks their potential. This guide covers the process step-by-step. SHENSHI brings expertise and innovation. Our solutions serve HVAC, renewable energy, and more. Visit https://en.shenshiec.com/ to explore our products. Let’s build a sustainable future together.

EEAT Compliance

- Expertise: Based on SHENSHI’s 20+ years of R&D.

- Authoritativeness: National high-tech status and patents.

- Trustworthiness: Certified quality and transparent history.