Fluid ice slurry crystals are very small, smooth, and rounded, and they reach every corner of the product to be cooled. This achieves the fastest heat transfer, evenly cooling the product immediately, and prevents the formation of potentially harmful bacteria, enzyme reactions, and discoloration. Fluid ice slurry helps maintain peak product freshness for a longer time.

Refrigeration

Solution

Products

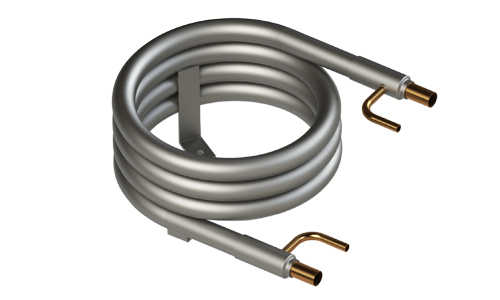

- Heat Exchanger for Ice Making Bins

An ice machine is a refrigeration mechanical device that generates ice by cooling water through an evaporator with refrigerants from a cooling system. It uses a refrigeration system with water as the medium, and ice is produced when the system is powered on and processed by the equipment. Shen's coaxial heat exchangers are commonly used in ice machines as condensers, where the heat absorbed during ice making is expelled through the condenser via the cooling system.

- Economizer

Coaxial tube economizer is actually a special heat exchanger, which is widely used in refrigeration and heat pump systems. The main role of the economizer is to increase efficiency in the system, especially in large commercial and industrial refrigeration systems.

Case Stories

Seafood Transport – Spoilage Reduced from 20% to Under 2%

A leading seafood exporter was losing 20% of inventory during long-haul transport due to slow, uneven cooling and bacterial growth. The installed fluid ice slurry system with coaxial tube heat exchangers achieved rapid, uniform cooling throughout the entire load. Spoilage dropped to below 2%, shelf life extended by 40%, and annual losses decreased by $500,000.

Pharmaceutical Cold Chain – Eliminated Temperature Excursions Entirely

A pharmaceutical distributor faced repeated temperature fluctuations outside the required 2–8°C range during vaccine transport over 1,000+ km routes, risking batch rejection and regulatory penalties. High-efficiency economized refrigeration units with precise heat transfer control were deployed. Result: temperature deviation kept within ±0.1°C, zero excursions or compliance issues recorded, and energy consumption reduced by 30%.

Food Processing – Cut Ice-Related Waste and Downtime

A large dairy processor experienced inconsistent ice quality and slow production cycles, leading to enzyme reactions, discoloration, and 15% waste of fresh milk batches. Ice-making bin heat exchangers were installed to optimize heat expulsion and produce uniform, round ice crystals. Ice production cycles shortened by 25%, waste fell by 18%, and plant uptime significantly improved within six months.

Service

According to your needs, we will upgrade your existing products through the latest technology, re-optimize the design, improve the efficiency and performance of the heat exchanger, and extend the service life.

Service support:We promise that during the one-year warranty period, if the product has quality problems, we will unconditionally provide you with a new product replacement service.

With nearly 20 years of heat exchanger manufacturing experience, Shen's technology has accumulated a wealth of professional knowledge. We will share with you tips on installation, use and troubleshooting to help you improve your operating skills and maintenance capabilities to keep your equipment running efficiently throughout its life cycle.

Download

Product Manual

- Product catalog of coaxial tube/shell and tube heat exchangers