JianDe Production Base

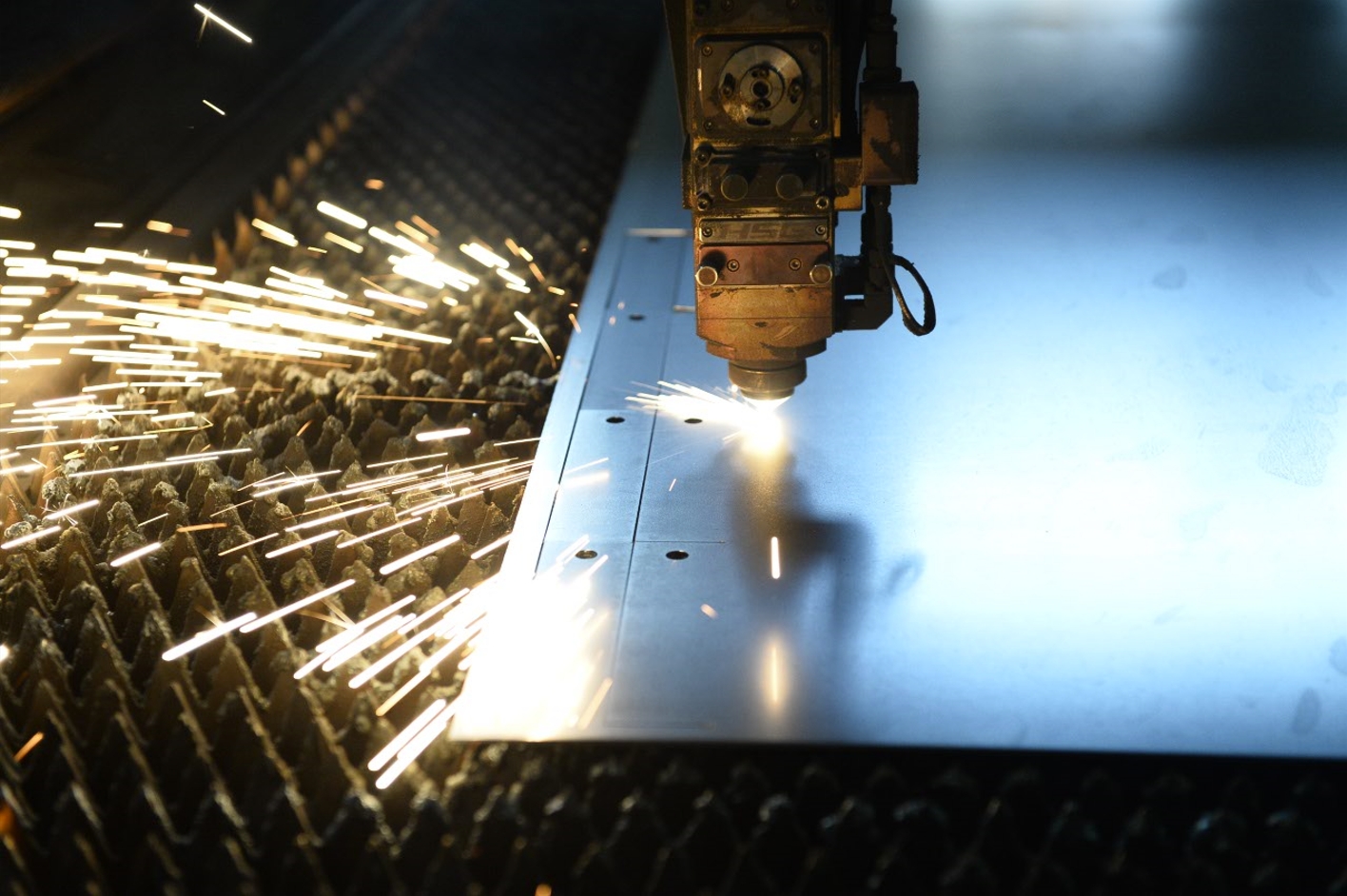

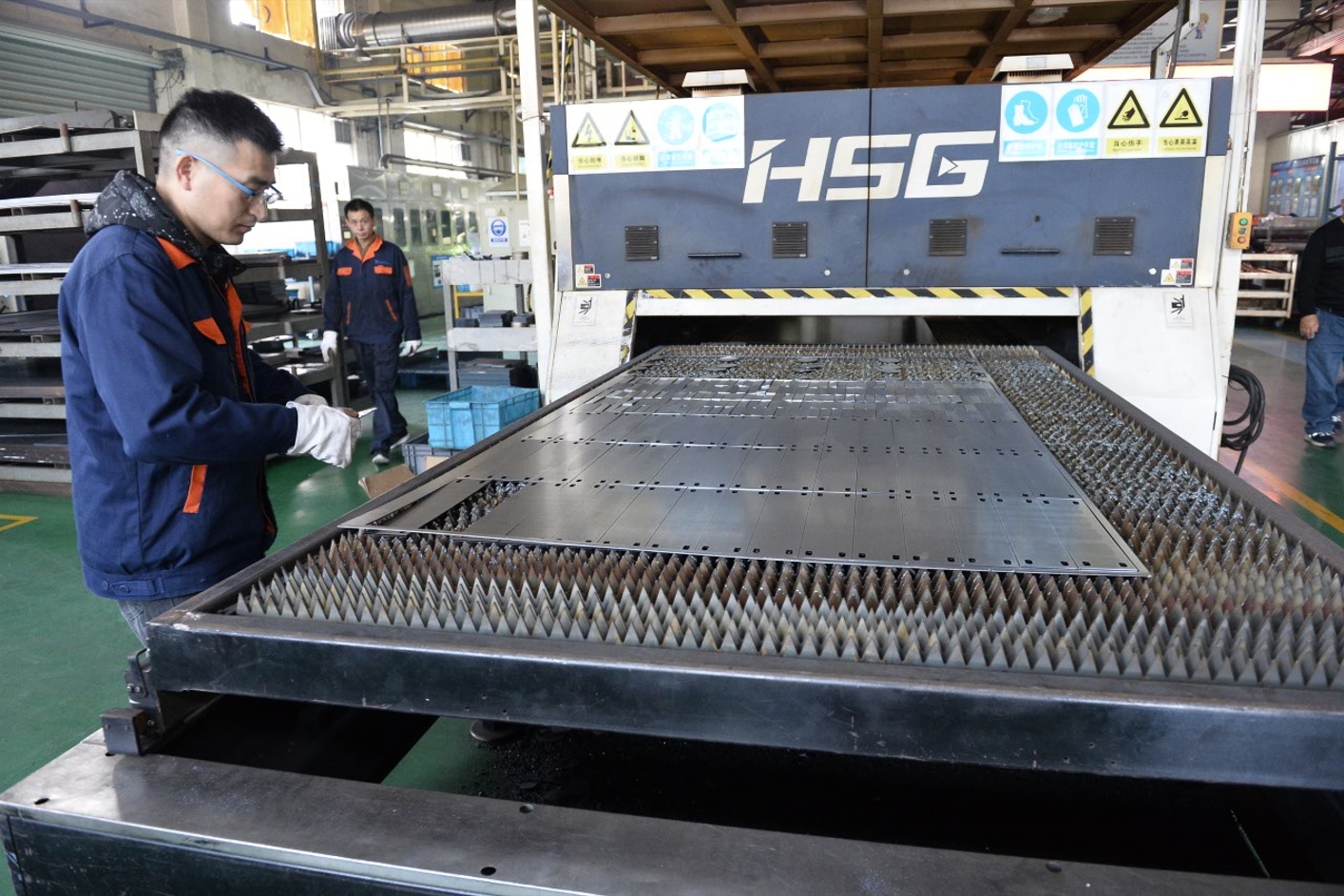

It has a production base of 44000m2, which is used for various auxiliary parts processing, component welding, finished product testing, packaging and so on. There are a number of production lines in the base, while equipped with modern production and processing equipment and online ERP, MES, OA management system, to produce all kinds of heat exchange products, the annual output can reach 1 million units (sets). Committed to the national "carbon peak, carbon neutral" strategy of low-carbon thermal management solutions, with special equipment production qualifications, with the domestic leading vacuum diffusion welding technology.

The main products include: coaxial tube heat exchanger, shell and tube heat exchanger, shell and coil heat exchanger, micro-channel heat exchanger, micro-channel reactor, micro-channel cold plate and so on.