An air heater is used to heat the air entering the hydrogen production system to reach the reaction temperature.

Hydrogen energy - Hydrogen production

Hydrogen Production Solutions

Products

- Steam Generator

The steam generator vaporizes the feed water into gas, which then enters the SOEC reactor to produce hydrogen.

Hydrogen ReformerThe hydrogen reformer performs reforming and heat exchange of fuels like methanol and water to produce hydrogen.

Application

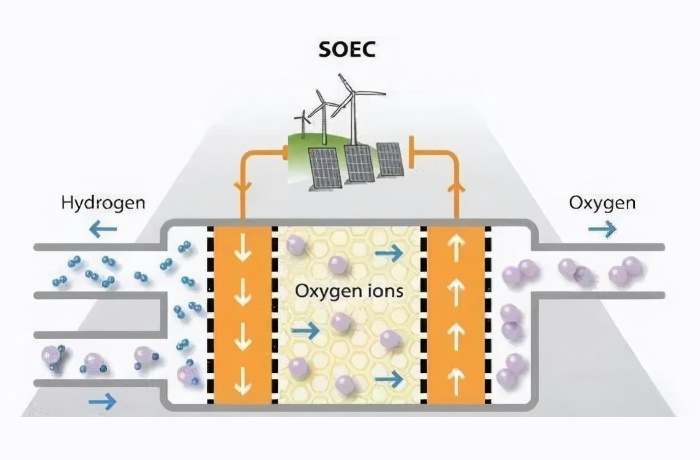

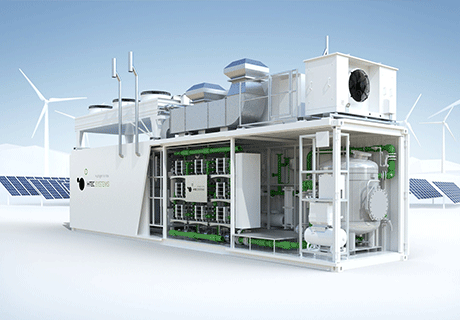

Heat exchangers used in SOEC hydrogen production systems can also be applied to SOFC power generation systems, whether for fuel preheating, steam generation, etc.

Heat exchangers from Shen's Technology can also facilitate waste heat recovery systems, using the circulating waste heat as a thermal source for pre-heat exchange.

Case Story

Shen's Technology provided a batch of methanol water preheaters for a methanol reforming hydrogen project.

With extensive experience and advanced technical strength, Hangzhou Shen's successfully designed and produced methanol water preheaters that meet project requirements. This preheater uses high-efficiency heat transfer materials and advanced thermal control technology to effectively preheat methanol and water, ensuring smooth reforming reactions.

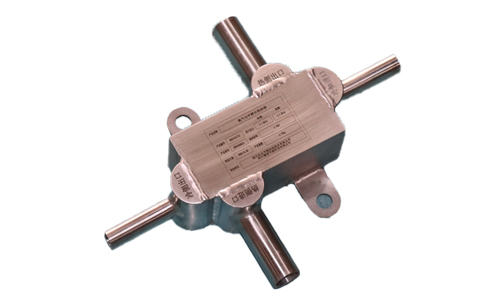

Shen's Technology successfully developed an SOEC (Solid Oxide Electrolysis Cell) heat exchanger for the hydrogen production industry.

The SOEC heat exchanger is a high-efficiency, stable heat exchange device developed by Hangzhou Shen's to meet the needs of the SOEC hydrogen production industry. It uses advanced materials and processes to improve the energy conversion efficiency and operational stability of the SOEC hydrogen production process.

Shen's Technology provided an alkaline solution cooler for an ALK hydrogen project.

This ALK hydrogen project aims to produce hydrogen through ALK reactions to meet market demand. During the ALK reaction, a large amount of heat is generated, necessitating a high-efficiency cooler to control the reaction temperature and ensure stable ALK hydrogen production.

Download

Product Manual

- Microchannel heat exchanger product sample