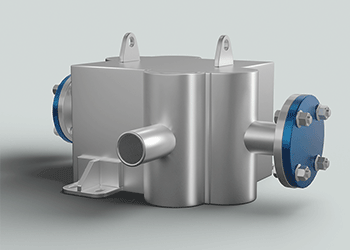

Used for cooling the discharge of the compressor, lowering the temperature of the compressed gas, facilitating the next stage of compression.

Gas Separation

Industrial gases like nitrogen (N2), oxygen (O2), argon (Ar), and carbon dioxide (CO2) are primarily sourced from air separation using cryogenic distillation in an air separation unit (ASU). Mass production doesn't cool air directly via adiabatic expansion due to limited work output and lower liquefaction temperatures increasing system volume.Instead, the compression process is key: intake air is first pressurized by a compressor (driven by a steam turbine) to several tenths of MPa. A booster compressor further compresses part of this air to higher pressure levels (several MPa) before expansion. This step is critical for thermal efficiency and gas liquefaction.

Home / Gas separation

Gas Separation Solutions

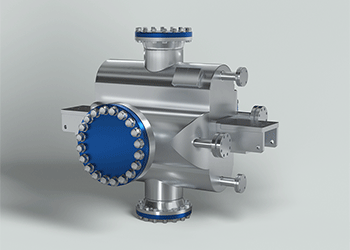

Shen's technology provides thermal management solutions for gas separation. The compressor intercooler and air separation cooler developed by Shen's Technology have small volume and high heat exchange efficiency, which effectively reduces the temperature rise caused by gas compression and improves the gas separation efficiency.

Related Products

- Air Separation Cooler

Liquefies and separates air to obtain N2, O2, CO2, Ar, Kr, Xe, and other gases.

Related Industry

In the process of gas liquefaction, huge cold energy is needed, and the heat exchanger of Shen Technology can use the cold energy generated by the gasification of other gases for industrial gas liquefaction.

File Download

Product Manual

- Microchannel Heat Exchanger Product Sample