Strong frost resistance

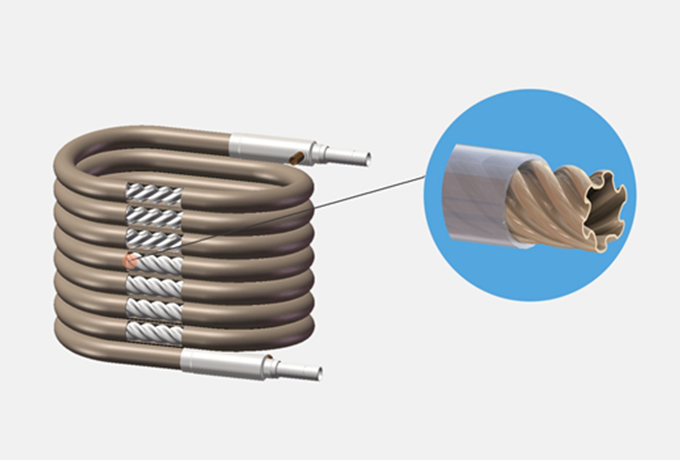

Spiral groove structure, good expansion and contraction performance, not easy to freeze and crack

Spiral groove structure, good expansion and contraction performance, not easy to freeze and crack

The cross-sectional size of the water side flow channel is large, and the fluid flows and flushes in a spiral, which is not easy to clog and scale.

Spiral groove structure greatly improves the heat transfer coefficient

Fewer welds reduce leakage risk, improve durability.

Spiral casing resists pressure, vibration, and impact better.

Stainless steel, titanium, nickel white copper, etc.

Applicable to the coal-to-electricity market, with high heat exchange efficiency and strong cooling, its modular design is applicable to a wide range of models.

Realize heat exchange between refrigerant and water or air to achieve the purpose of cooling or heating.

Realize heat exchange between refrigerant and water or air to achieve the purpose of cooling or heating.

Can be used as an evaporator or condenser, providing a variety of appearance options, high energy efficiency, compact structure.

High heat exchange efficiency, compact structure, good anti-fouling and durability, easy maintenance, safe and reliable.

Designed for the properties of supercritical CO2, it has the characteristics of high pressure resistance and high heat transfer efficiency.

Compact structure, effective space saving, high heat exchange efficiency, good reliability.

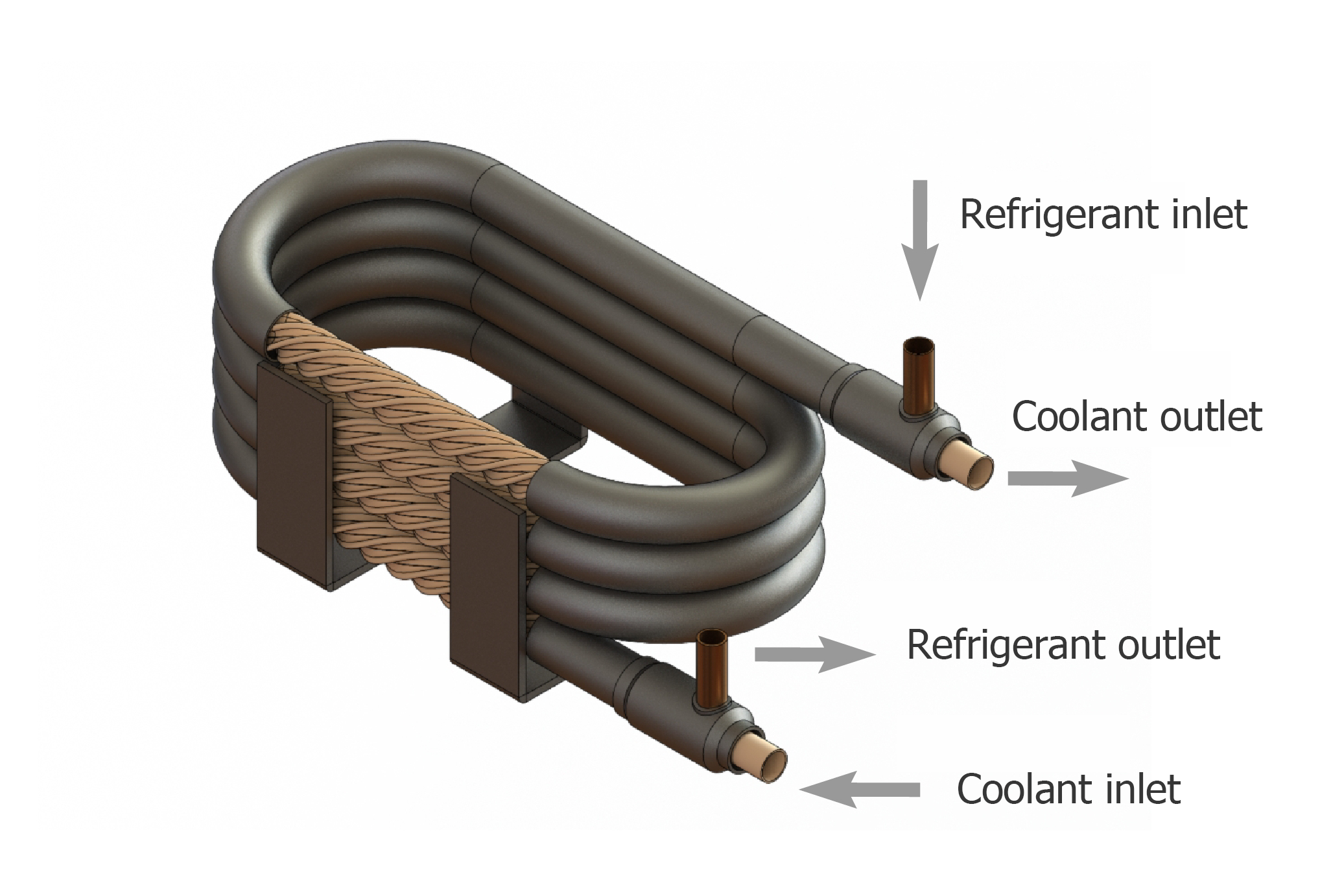

A high-efficiency heat exchanger composed of a high-efficiency internal threaded pipe bent into an Ω shape and a plastic shell, which cleverly combines the characteristics of a shell and tube heat exchanger and a plate heat exchanger.

A high-efficiency heat exchanger composed of a high-efficiency internally threaded pipe bent into an Ω shape and a plastic shell, which cleverly combines the characteristics of a shell and tube heat exchanger and a plate heat exchanger.

Shenshi Technology heat exchanger uses fluid ice slurry as heat exchange medium to achieve fast and uniform heat transfer, quickly cool products, and reduce potential harmful bacteria formation, enzyme reaction and discoloration, which can maintain peak product freshness.

In the refrigeration system, it is an efficient and energy-saving heat exchange equipment, mainly used for cooling or freezing medium to achieve the purpose of keeping food fresh during storage or transportation.

In the refrigeration cycle of a screw or centrifugal compressor, the economizer is used to further cool the refrigerant flowing out of the evaporator (i.e., subcooling) to improve the efficiency of the entire system.

Shenshi Ice Maker Coaxial Heat Exchanger is mostly used for the condenser of the ice maker. The heat absorbed during the ice making process is discharged from the condenser through the refrigeration system.

The inner and outer tubes of Shenshi water purifier coaxial heat exchanger are made of food-grade stainless steel, and provide safe and reliable ice water or hot water for water purifier users through refrigeration or heat pump system

Realize heat exchange between refrigerant and water or air to achieve the purpose of cooling or heating.

Shenshi dishwasher coaxial heat exchanger provides hot water for the dishwasher through the heat pump system to ensure the normal and efficient operation of the dishwasher.

Shenshi washing machine coaxial heat exchanger products can be used in washing machines. We currently have standardized products, and we can also customize related products according to customer needs

Shenshi Technology's coaxial heat exchanger is unique in the HVAC field with its advantages of high efficiency, reliability and economy. The product structure optimizes space utilization while ensuring heat exchange efficiency.

The goal of using heat exchangers is to ensure temperature control, energy efficiency and product quality, helping to keep food, medicines and other temperature-sensitive items at suitable temperature conditions to extend their shelf life and ensure their safety.

The key role of heat exchangers in home appliances and industry is to improve energy efficiency, reduce costs, and promote sustainable development. Through precise heat control, it promotes the improvement of equipment performance and production efficiency.

Heat transfer is an indispensable part of the heat pump system. Shenshi Technology's shell-and-tube heat exchanger has a core technology patent. It is composed of a high-efficiency internal threaded tube bent into an Ω shape and a plastic shell. It has a compact structure and high heat exchange efficiency, enabling the heat pump system to efficiently heat the swimming pool water.

Effectively regulate the temperature of ship systems, improve the performance of engines and equipment, while ensuring that fuel and other fluids are transported within a suitable temperature range, promoting ship safety and efficiency.

Through efficient heat transfer, optimize the temperature control of the energy system, improve the performance of power generation equipment and energy utilization efficiency.

Gain complete peace of mind knowing your operations are safeguarded against unexpected downtime.

Shenshi creates a customized maintenance schedule tailored to your specific usage patterns, ensuring your heat exchanger remains reliable, efficient, and secure for the long haul.

Restore your equipment's peak performance with cleaning protocols designed specifically for your unique application.

Shenshi analyzes your system's condition to safely remove sediment and scale, giving you the confidence that your efficiency is maximized without compromising equipment integrity.

Experience the security of having a professional partner on standby, ready to protect your production continuity.

Shenshi's team doesn't just fix issues; we provide precise, personalized solutions that address the root cause, building a foundation of trust and long-term operational safety for your business.

Go beyond basic service with our precision testing and leakage risk assessments, designed to give you absolute certainty.

Shenshi provides data-driven advice and advanced inspections, ensuring you can resume production with full confidence in your equipment's safety and reliability.