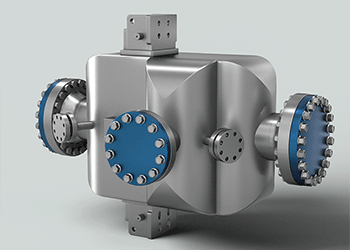

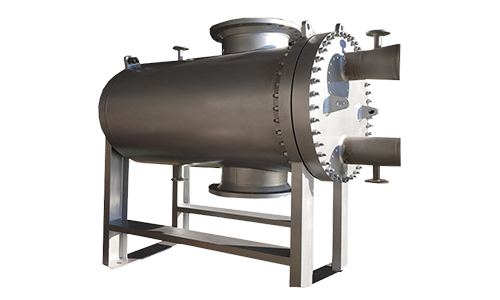

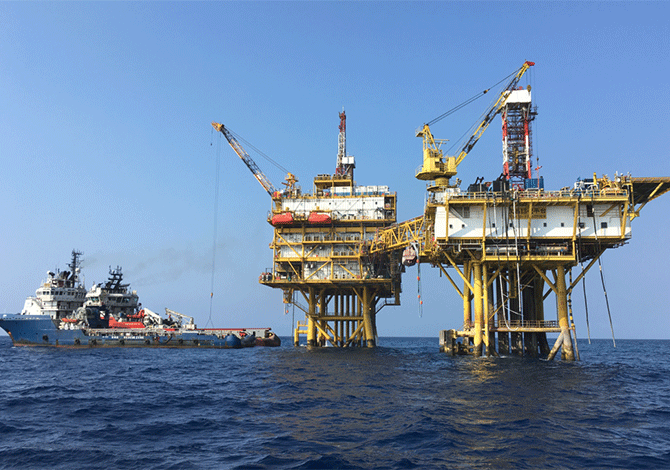

Heat exchanger used for cooling LNG or other working fluids on offshore oil and gas platforms or LNG vessels.

FSRU, FLNG, FPSO, Oil And Gas Platform

Solution

Related Products

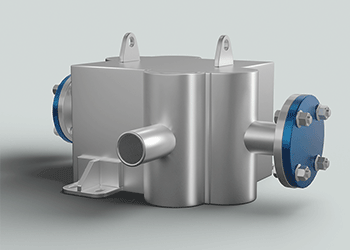

- Compressor Aftercooler

Cooling system used in natural gas compressors to control the temperature of compressed natural gas.

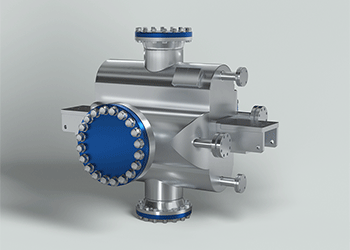

BOG Heat ExchangerUsed in BOG processing systems on LNG vessels or at LNG receiving stations, capable of reliquefying LNG that has evaporated during transmission due to temperature rise, reducing natural gas loss.

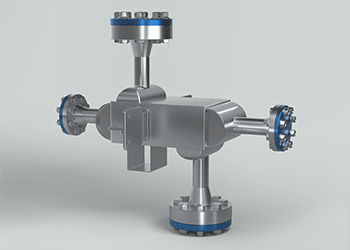

Wet (Natural) Gas CoolerUsed in cooling systems to achieve natural gas cooling through heat exchange between water or seawater and natural gas.

- BOG Heat Exchanger

BOG processing systems used in LNG ships and LNG receiving stations can reliquify LNG that is volatilized due to rising temperatures during transmission and reduce natural gas losses

Related Application

Suitable for the liquefaction of industrial gases such as hydrogen, LNG, propane, and ammonia, facilitating their transportation.

During the process of liquid gas vaporization, a significant amount of cold energy is released. Shen’s Technology heat exchangers can utilize this energy to produce other gas products or generate electricity.

Related Service

Preventive Maintenance

Through regular preventive maintenance, potential issues can be identified and resolved promptly, extending the service life of the heat exchanger, maintaining stable performance, improving energy efficiency, reducing the risk of failures, and ensuring the heat exchanger remains in optimal condition.

Cleaning

During operation, the internal channels of the heat exchanger may accumulate deposits, scale, and other impurities, leading to reduced heat transfer efficiency, affecting equipment performance and energy efficiency, and ultimately impacting production efficiency and equipment lifespan. Shen’s Technology will recommend cleaning methods for the heat exchanger based on the equipment and actual application to maintain optimal operating conditions.

Service Support

Shen’s Technology's professional service team is always on standby, ready to quickly and accurately identify the problem and provide the best solution. Beyond resolving current issues, we aim to help you prevent potential risks through our professional services.

Additional Services

Additional services are value-added assurances provided by Shen’s Technology beyond the basic services. Shen’s Technology uses precise testing techniques to comprehensively inspect equipment components and identify potential leakage risks. Based on the test results, we will recommend the best measures to help you resume production.

File Download

Product Manual

- Microchannel heat exchanger product sample