Hangzhou Micro Control Energy Saving Technology Co., LTD

A wholly owned subsidiary of Hangzhou Shenshi Energy Conservation Technology Co., Ltd.,specializing in high-efficiency, compact heat exchangers.

Leveraging China-leading vacuum diffusion welding technology, we deliver low-carbon thermal management solutions aligned with the national Carbon Peak & Carbon Neutrality strategy.

Home / hzwk

Production Equipment

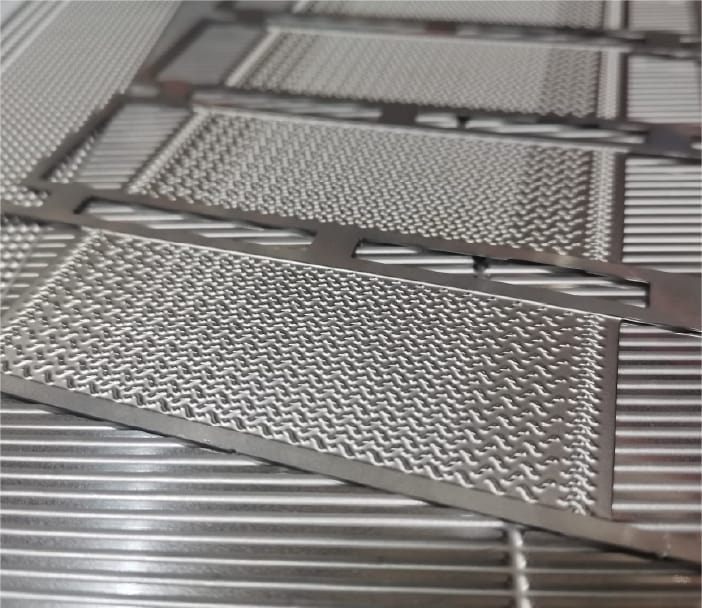

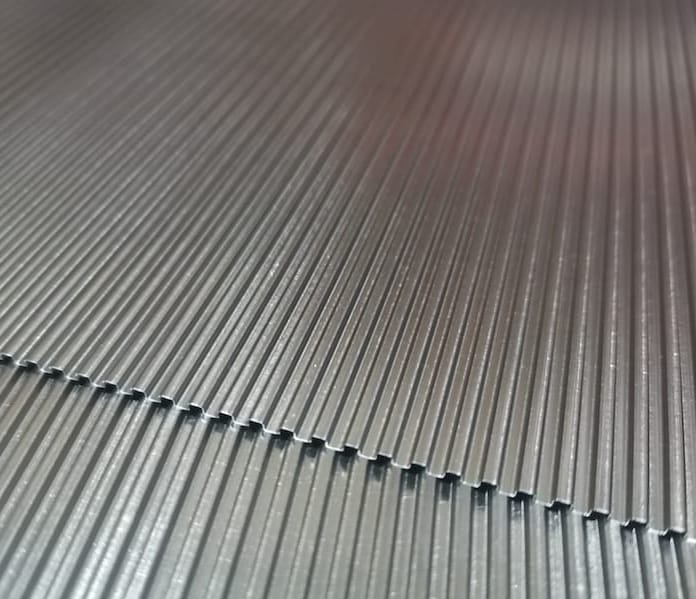

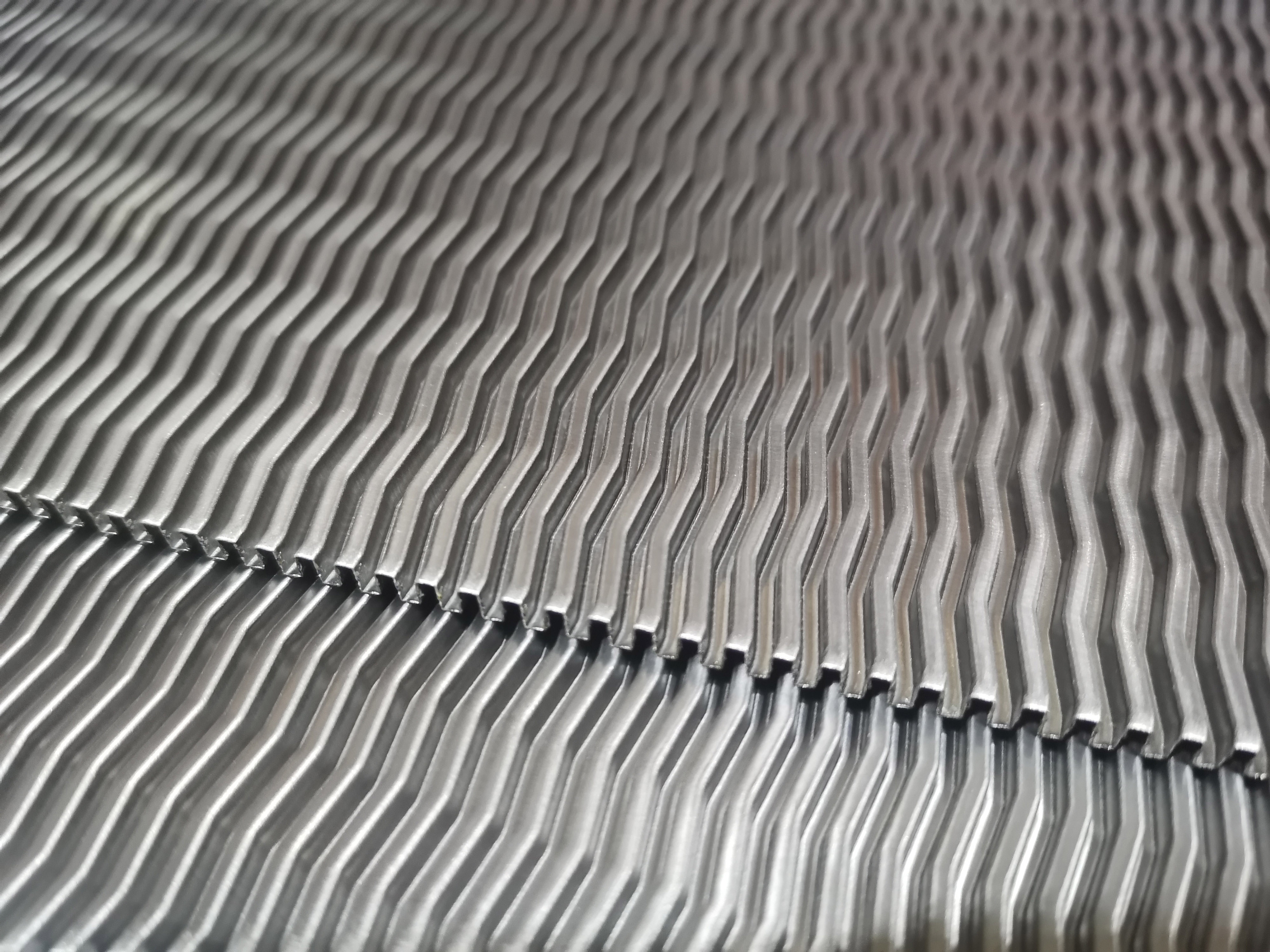

Hangzhou Microcontrol production base has the ability of machining, welding, assembly, test and inspection, and can develop and produce micro-channel heat exchangers, micro-channel cold plates, diffusion welded plate fin heat exchangers, micro-environment systems, etc. The production base is equipped with vacuum diffusion welding furnace, high temperature brazing furnace, welding robot, wire cutting, processing center, laser cutting machine, automatic pipe bending machine, fin stamping machine and other processing equipment.

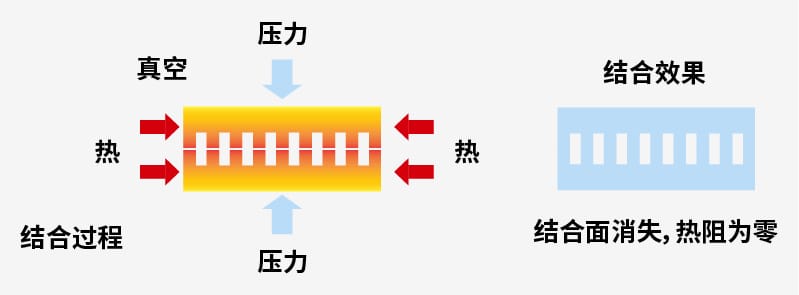

Diffusion Welding Technique

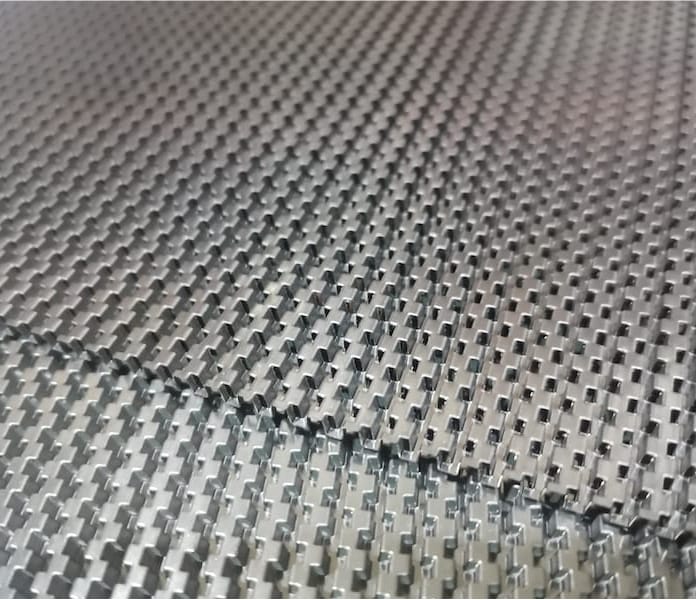

The principle is that a number of layers of different thickness of the metal sheet through the flow channel and shape processing, in the vacuum state to apply appropriate pressure and temperature, so that the metal surface is fully combined. The heat exchanger core made of diffusion welding technology has the advantages of no joint, no weld, no any other type of potential fault point, and its strength after welding can reach more than 95% of the base material to ensure the excellent performance of the product.

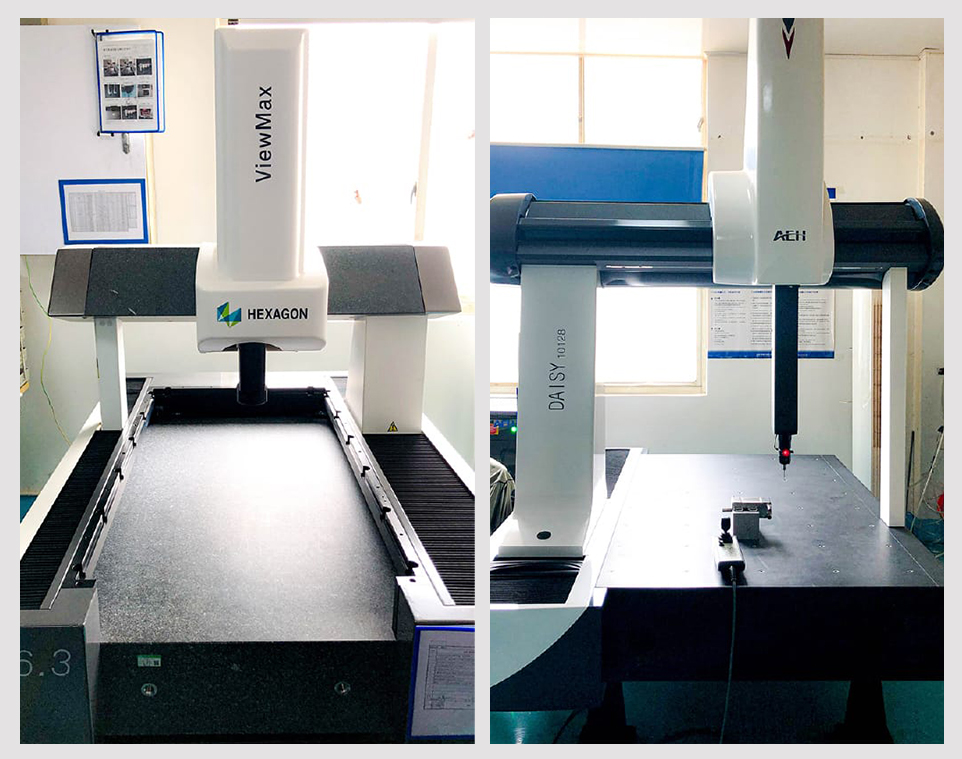

Quality

Hangzhou Micro control with "commitment to quality and safety" as the core concept, from product quality to manufacturing industry, and then to employee safety, layers of control, strict management. We strictly enforce the highest standards of health and safety. Hangzhou Micro control always puts customers first.

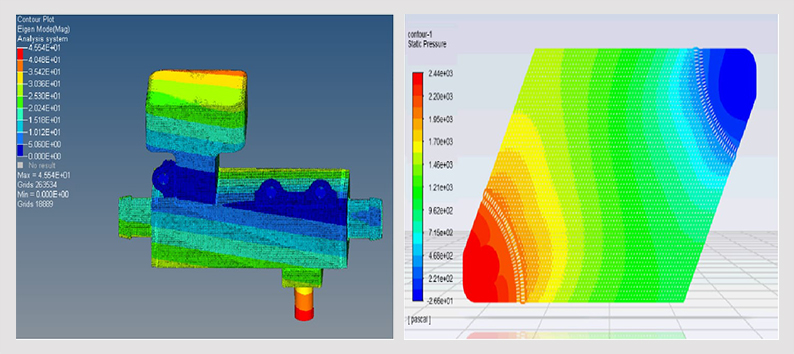

Design Calculation

According to the accumulated experience of calculation, simulation and test of micro-channel and plate-fin products for many years, the calculation formula and correction coefficient are fitted to ensure the accuracy of the design, and the unique design method of heat exchanger is formed, which can provide reasonable and feasible design schemes according to different environment, appearance and heat transfer needs.

Simulation Technology

After a large number of simulation cases and the actual delivery of product test data, a set of targeted optimization simulation methods are summarized and formed, which improves the accuracy and efficiency of heat transfer and flow resistance simulation. Micro-size processing technology: micro-channel (minimum equivalent diameter up to 0.1 mm) is processed on the substrate through micro-processing technology, which greatly increases the heat transfer area, causes the fluid to form turbulent flow, and improves the heat transfer capacity.