Dominant Service

Diverse Material Choices:

316L, duplex steel, C276TA10, Zr, silicon carbide and other materials can be selected according to actual working conditions;Customization of Core Components:

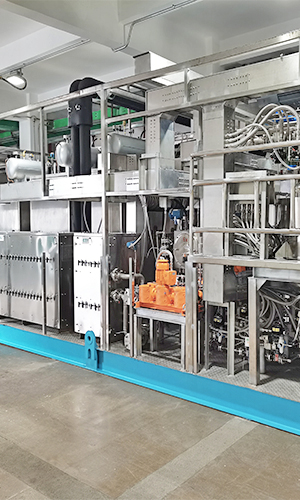

Covering microchannel reactors, microchannel mixers, microchannel heat exchangers, tubular reactors and other equipment;Flexible Application form:

Multiple flow channel combination design, multiple feeds, zone temperature control, can be used alone or in series;Standardization of Pipe Sizes:

Standard imperial or metric interface, also available for customization, convenient for connection with other equipment systems;Seamless Integration with Industrialization:

Seamless connection from laboratory development, small-scale trials, pilot tests to large-scale industrial production, with basically no scale-up effect, easy to achieve industrialization;