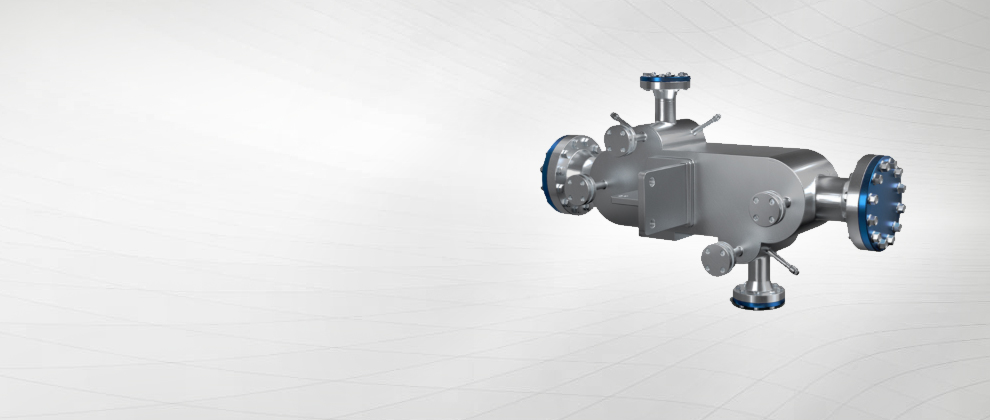

Variety Of Material Selection

316L, duplex steel, Ha C276TA10, Zr, silicon carbide and other materials can be selected according to the actual working conditions.

Core Device Customization

Covering microchannel reactor, microchannel mixer, microchannel heat exchanger, tube reactor and other equipment.

Flexible Application Form

A variety of flow channel combination design, can be multi-strand feed, partition temperature control, can be used alone or multiple groups in series.

Nozzle Sze Standardization

Standard imperial or metric interfaces are also available for personal customization to facilitate connection to other equipment systems.

Seamless Industrialization

From laboratory development, small trials, pilot trials, to industrial large-scale production seamless docking, and basically no amplification effect, easy to achieve industrialization.

Service Diversification

We can provide special design and customized services for customers in different fields, and strive to meet the various needs of customers.

Quality Assurance

The product quality guarantee period shall be 18 months after the contract is signed or one year after it is put into use.