High Efficiency And Energy Saving

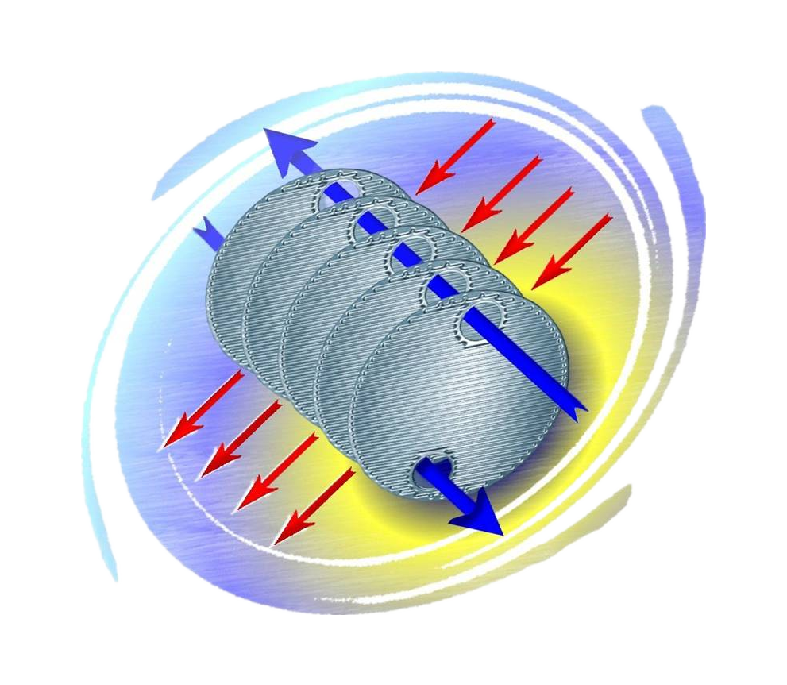

Large sheet surface and variable process combination ensure heat transfer efficiency.

Large sheet surface and variable process combination ensure heat transfer efficiency.

It takes up less space and optimizes site use.

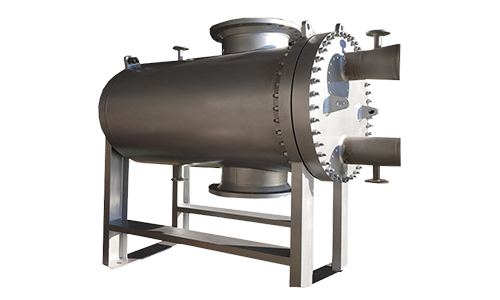

The robust housing structure is designed to withstand high pressures and temperatures.

No rubber gasket, body material welding, no welding appendages.

Applicable to Marine shipbuilding, hydrogen energy and other industries.

Designed for safe and efficient steam handling on liquefied natural gas (LNG) carriers.

Shen's products are widely used in floating storage and regasification units (FSRU), Floating liquefied natural gas units (FLNG), floating production storage and offloading units (FPSO) and oil and gas platforms in the offshore Marine industry.

With efficient heat transfer technology, Shen's technology helps the efficient production and safe storage and transportation of hydrogen energy, and promotes the sustainable development of green electricity. The products play a key role in hydrogen production, storage and transportation of hydrogen and hydrogen supply in the field of hydrogen energy.

Gain complete peace of mind knowing your operations are safeguarded against unexpected downtime.

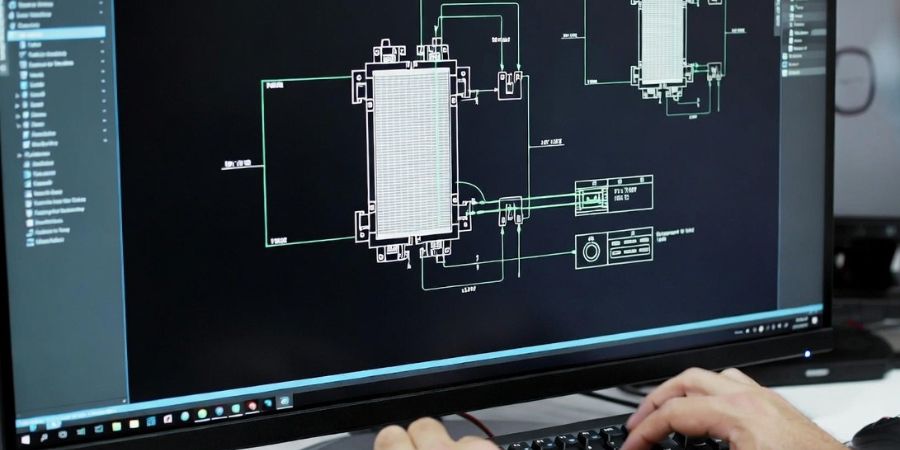

Shenshi creates a customized maintenance schedule tailored to your specific usage patterns, ensuring your heat exchanger remains reliable, efficient, and secure for the long haul.

Restore your equipment's peak performance with cleaning protocols designed specifically for your unique application.

Shenshi analyzes your system's condition to safely remove sediment and scale, giving you the confidence that your efficiency is maximized without compromising equipment integrity.

Experience the security of having a professional partner on standby, ready to protect your production continuity.

Shenshi's team doesn't just fix issues; we provide precise, personalized solutions that address the root cause, building a foundation of trust and long-term operational safety for your business.

Go beyond basic service with our precision testing and leakage risk assessments, designed to give you absolute certainty.

Shenshi provides data-driven advice and advanced inspections, ensuring you can resume production with full confidence in your equipment’s safety and reliability.