Heat exchanger used on offshore oil and gas platforms or LNG carriers to cool LNG and other process fluids.

Offshore Ship

Solution

Products

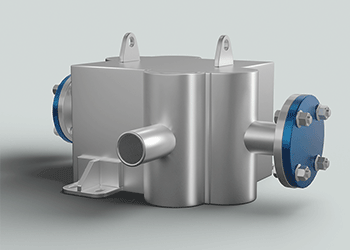

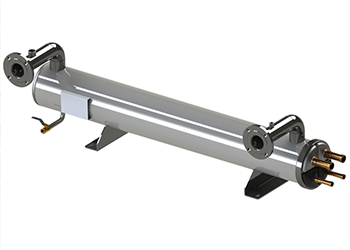

- Compressor Aftercooler

Cooling system for natural gas compressors, controlling the temperature of the compressed natural gas.

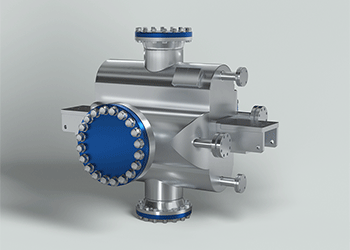

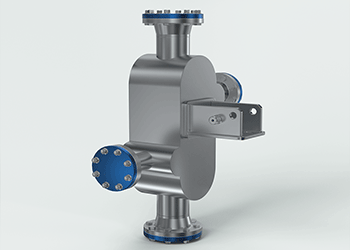

BOG Heat ExchangerUsed in LNG carriers and LNG receiving stations for BOG treatment systems to re-liquefy LNG that vaporizes due to temperature increases during transportation, reducing natural gas loss.

Moisture CoolerUsed in cooling systems to achieve natural gas cooling through heat exchange with water or seawater.

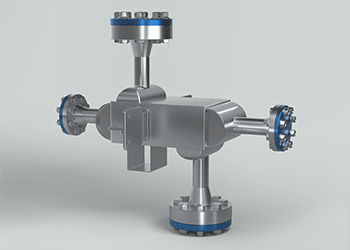

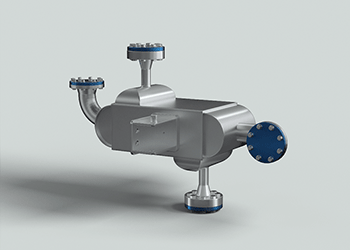

High Pressure VaporizerUsed in FGSS high-pressure systems, generally at pressures around 300Bar, to vaporize natural gas.

- Low Pressure Gasifier

Used in FGSS low pressure systems, generally at 6-8 bar, to gasify natural gas.

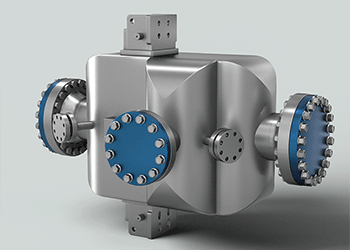

- Cooler

Heat exchangers used for offshore oil and gas platforms or LNG ships to cool LNG and other working fluids

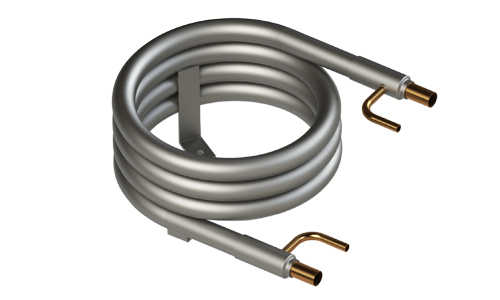

- Marine Air Conditioning

For air conditioning systems on ships and yachts, Shenshi Technology provides customers with efficient heat exchange solutions

Industry

The Floating Storage Regasification Unit (FSRU) is a facility for receiving, storing, and regasifying liquefied natural gas (LNG). It is typically a specially designed and modified vessel capable of receiving and storing LNG, and then regasifying it as needed to supply pipelines or other facilities.

The Floating Production, Storage, and Offloading (FPSO) unit is used for offshore oil and gas extraction and processing. It has the capability to produce, store, and offload oil or gas. It can be deployed at offshore oil fields to extract and process oil or gas from wells, then store it and transport it to land terminals via pipelines or vessels.

The Floating Liquefied Natural Gas (FLNG) facility is designed to liquefy and store natural gas directly at sea. FLNG units can be deployed near offshore oil and gas fields to cool and compress natural gas, turning it into liquefied natural gas (LNG), which is then stored and transported to land terminals or other destinations.

An offshore oil and gas platform is a large structural facility located at sea for drilling and extracting oil and gas, and temporarily storing it until it can be transported to land-based refineries for processing. Often, the platform includes extraction facilities and living quarters for personnel. Depending on the situation, the platform can be fixed to the seabed, may be an artificial island, or float on the sea. Multiple seabed wells can also connect to a single platform via pipelines.

The Floating Gas Supply System (FGSS) is used to supply gas fuel to offshore vessels or platforms. FGSS is primarily used for LNG carriers, LPG carriers, and other offshore vessels requiring gas fuel. It transfers liquefied gases (such as LNG or LPG) from storage facilities to receiving vessels or platforms and supplies fuel through pipeline connections.

Marine air conditioning systems are necessary for adjusting temperatures on offshore vessels, yachts, naval ships, and other types of ships. Shen's technology provides thermal management solutions for marine air conditioning, with efficient coaxial heat exchangers enhancing system performance.

Application Cases

Compact PCHE Boosts FPSO Production Efficiency

SHENSHI's Printed Circuit Heat Exchangers (PCHE) deliver superior compactness and high heat transfer rates for FPSO units. Facing limited deck space and harsh offshore conditions, our solutions optimize hydrocarbon processing, reduce equipment footprint, lower weight, and enhance overall production rates for sustained offshore operations.

High-Performance Heat Exchangers for FSRU Regasification

SHENSHI provides durable coaxial and plate-shell heat exchangers tailored for FSRU vessels. Addressing challenges like BOG management and extended downtime in LNG regasification, our products ensure reliable performance, minimize energy loss, accelerate startup times, and support seamless gas supply to pipelines.

Reliable Preheaters Enhance Offshore Platform Output

SHENSHI's advanced aftercoolers and preheaters support offshore oil & gas platforms. Overcoming issues of compressor overheating and low thermal efficiency in remote environments, our ultra-large PCHE units (up to 12MW) improve cooling, boost production capacity, and ensure long-term reliability in extreme conditions.

Partner with Shenshi

Request Your Customized Thermal Management Solution

Service

Download

Product Manual

- Product catalog of coaxial tube/shell and tube heat exchangers

- Microchannel heat exchanger product sample