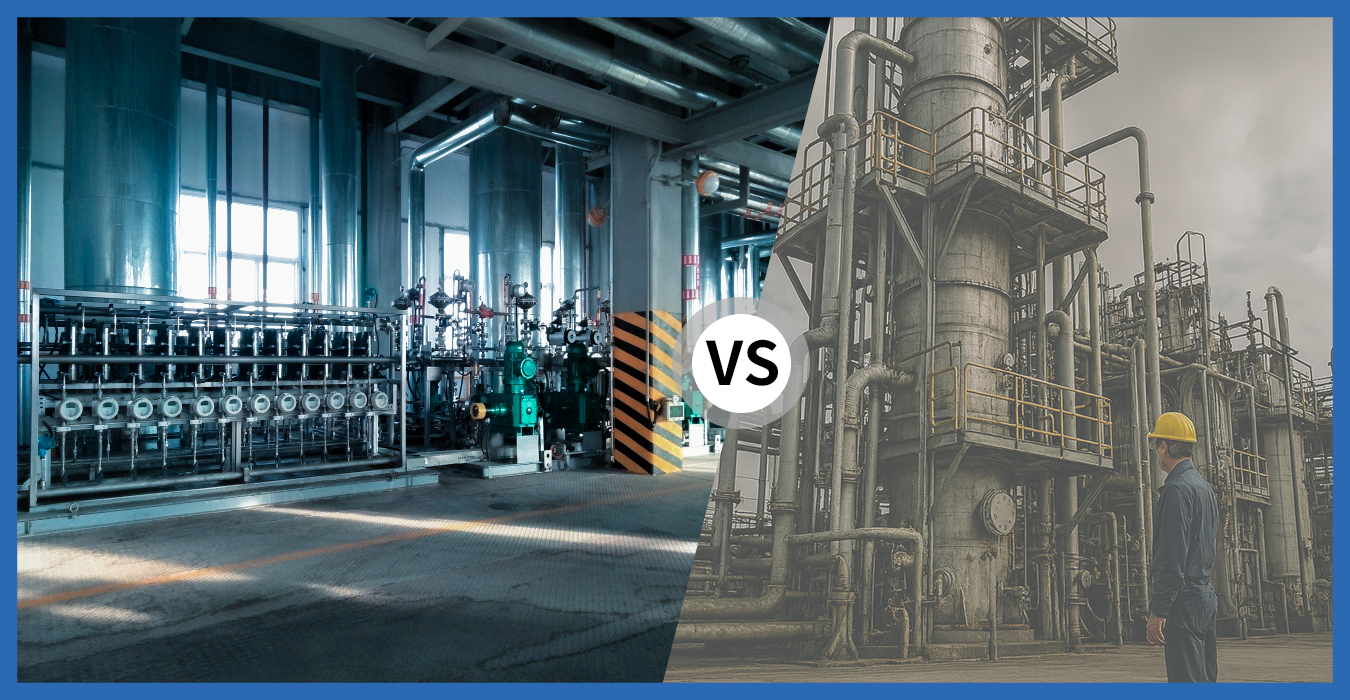

Lower OPEX and CAPEX

Higher yields resulting from more consistent, higher purity output leads to Lower CAPEX (capital expenditure)

Higher yields resulting from more consistent, higher purity output leads to Lower CAPEX (capital expenditure)

Micro chemical reaction has almost • 100X Higher Mass Transfer • 1000X Better Heat Transfer • 1000X Lower Reaction Volume • 50X Better Residence Time Distribution

Reduction in or elimination of solvent use is a particularly significant environmental benefit associated with micro chemical reactor products.

The most advanced way of making fine chemicals and medicine, with self monitoring and continues flow for the best output and efficiency.

Micro chemical reaction could reduce the risk of catastrophic events, particularly at industrial plant scale.

Micro chemical reaction could reduce the risk of catastrophic events, particularly at industrial plant scale.

Higher yields resulting from more consistent, higher purity output leads to Lower CAPEX (capital expenditure)

Reduction in or elimination of solvent use is a particularly significant environmental benefit associated with micro chemical reactor products.

Micro chemical reaction can ensure highly consistent product quality from lab bench to industrial production due to its precise chemical reaction control.

Micro chemical reaction has almost

• 100X Higher Mass Transfer

• 1000X Better Heat Transfer

• 1000X Lower Reaction Volume

• 50X Better Residence Time Distribution

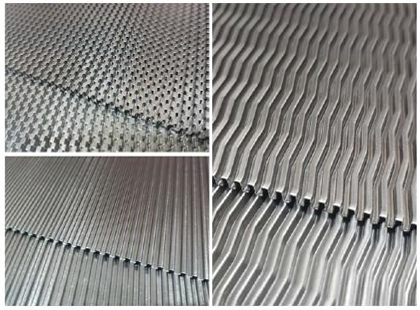

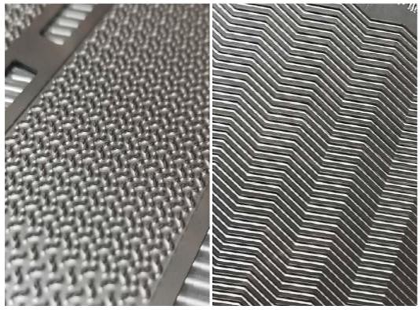

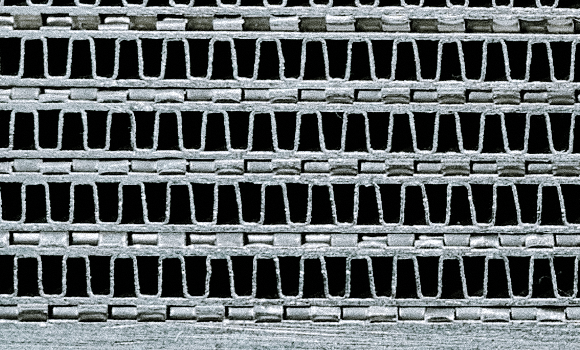

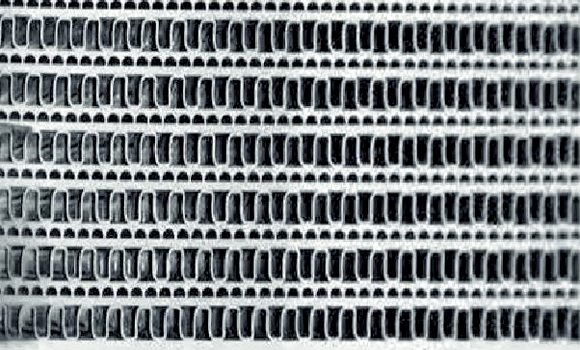

self-developed fin types include zigzag,straight, corrugated, etc. (channel size 1.5mm~5mm)

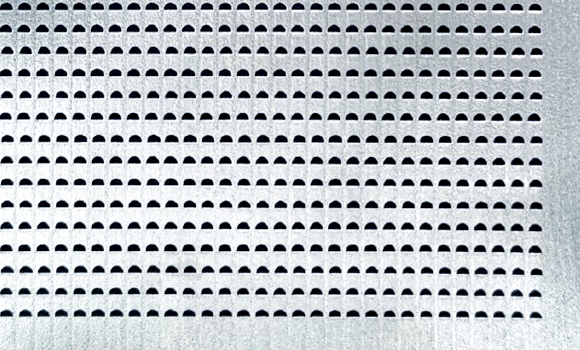

micro-channels (minimum equivalent diameter up to 0.1mm)are processed on the substrate by etching technology

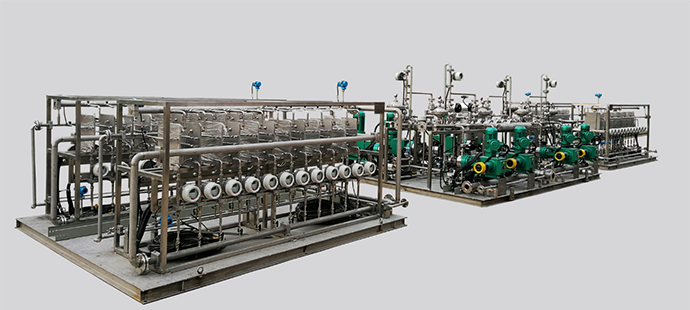

A miniaturized reaction device that integrates multiple microchannel reaction units.

Highly efficient mixing and heat transfer are achieved through the rotating flow in the spiral tube.

Use the fluid mechanics effect in the microchannel to achieve rapid and uniform mixing.

Miniature reaction device suitable for laboratory research.

An integrated reaction device that combines micro-reaction technology and continuous flow technology.

Multifunctional universal fluid chemistry microchannel reactor.

Multifunctional universal fluid chemistry microchannel reactor.

General fluid chemistry research and development equipment.

Used in drug synthesis, catalytic reactions, crystal engineering, purification, and separation, offering advantages such as high efficiency, speed, precision, and strong controllability. Accelerates new drug development and improves production efficiency.

Features high heat and mass transfer efficiency, optimizing key processes such as heavy oil cracking. Supports the development of new processes and promotes continuous, efficient, and low-cost petrochemical production.

Enhances synthesis efficiency and product quality, accelerates the development of new pesticides, and promotes continuous and automated pesticide production while reducing costs.

Materials such as 316L, duplex steel, Hastelloy C276, TA10, Zr, and silicon carbide can be selected according to actual working conditions.

Includes microchannel reactors, microchannel mixers, microchannel heat exchangers, and tubular reactors, among other equipment.

Various flow channel combinations available, with options for multi-stream feed and zonal temperature control. Can be used individually or in multiple series configurations.

Standard imperial or metric interfaces are available, with custom options also offered, facilitating easy connection with other equipment systems.

Seamless integration from laboratory development and pilot testing to full-scale industrial production, with minimal scale-up effects, making industrialization easier to achieve.

Provides specialized design and customization services for clients in various fields, fully meeting their diverse needs.

The product quality guarantee period is 18 months after the contract is signed or one year after the product is put into use.