The air heater heats the air entering the hydrogen production system to the reaction temperature.

Hydrogen Energy Source

Solution

Related Products

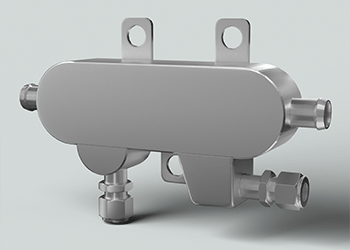

- Steam Generator

The steam generator vaporizes the feed water into gas, which enters the SOEC reactor to produce hydrogen.

Hydrogen ReformerThe hydrogen reformer performs reforming heat exchange on fuels such as methanol and water to produce hydrogen.

- Hydrogen Liquefaction Heat Exchanger

The hydrogen liquefaction plate-fin heat exchanger exchanges heat between hydrogen and gases such as nitrogen, cooling them to a liquid state.

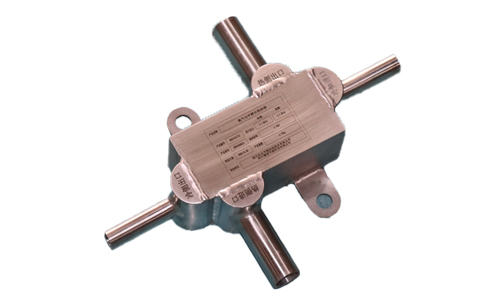

- Fuel Cell Hydrogen Preheater

The hydrogen preheater preheats the hydrogen entering the stack, speeding up the stack start-up process, thereby quickly starting the hydrogen fuel cell vehicle.

Hydrogen Compressor CoolerThe hydrogen compressor cooler primarily cools the compressed hydrogen to prevent hazards due to excessively high compression temperatures.

Hydrogen Station CoolerThe hydrogen station cooler reduces the temperature of hydrogen refueled at the hydrogen station, ensuring safe refueling.

Related Application

Shenshi Technology provides heat exchangers for SOEC systems in the field of hydrogen production. SOEC high-temperature hydrogen production technology is one of the newly developed hydrogen production technologies in recent years. Compared with traditional PEM electrolyzers and alkaline electrolyzers, it has the advantages of high efficiency, low energy consumption, reversibility, and low cost.

Shenshi Technology's hydrogen liquefaction plate-fin heat exchangers facilitate hydrogen storage and transportation. Liquid hydrogen transportation offers advantages such as high hydrogen storage density, low transportation cost, high vaporization purity, low storage and transportation pressure, and high safety, effectively controlling overall costs without involving complex unsafe factors during transportation.

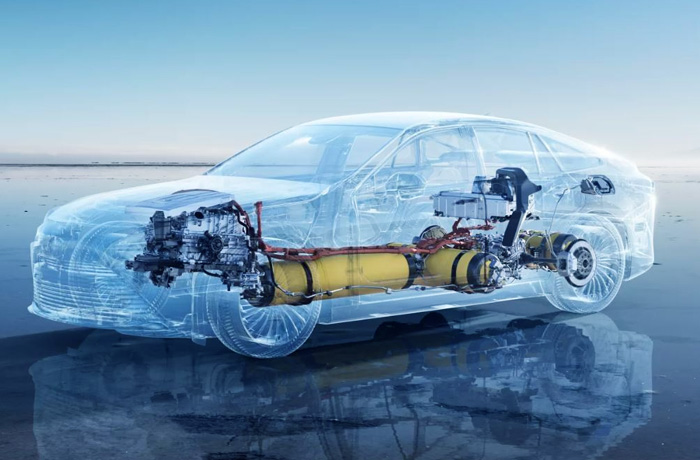

Shenshi Technology has developed hydrogen fuel cell preheaters, hydrogen station hydrogen coolers, and compressor coolers to provide effective thermal management solutions for the current hydrogen supply end. At present, the main application of hydrogen in the civilian sector is hydrogen fuel cell vehicles. Shenshi Technology's preheaters solve the cold start problem of fuel cell vehicles, and hydrogen coolers ensure the safety of hydrogen refueling.

Application Cases

Revolutionizing SOEC Hydrogen Production with High-Efficiency Heat Exchangers

Shenshi's SOEC air heaters and steam generators slash energy costs by 30% and boost output efficiency, solving your high production expenses and slow scalability—delivering clean, affordable H2 at industrial scale.

Streamlining Liquid Hydrogen Logistics for Seamless Global Delivery

Our plate-fin liquefaction exchangers ensure 99.9% purity and cut transport risks by 50%, tackling your storage density woes and safety vulnerabilities—enabling reliable, low-pressure H2 flow from plant to market.

Accelerating Safe Hydrogen Refueling for Zero-Emission Mobility

Shenshi's pre-heaters and station coolers eliminate cold-start delays and overheating hazards, addressing your refueling safety bottlenecks and vehicle downtime—fueling faster adoption of green transport fleets.

Partner with Shenshi

Request Your Customized Thermal Management Solution

Related Service

Preventive Maintenance

Through regular preventive maintenance, potential issues can be identified and resolved in a timely manner, extending the lifespan of heat exchangers, maintaining stable performance, improving energy efficiency, reducing failure risks, and ensuring that heat exchangers are always in optimal condition.

Cleaning

During operation, heat exchanger internal channels may accumulate deposits, scale, and other impurities, leading to reduced heat transfer efficiency, affecting equipment performance and energy efficiency, and impacting production efficiency and equipment lifespan. Shenshi Technology will recommend heat exchanger cleaning methods based on the equipment and actual application to maintain good operating conditions.

Service Support

The professional service team at Shenshi Technology is always on standby to quickly and accurately identify the problem and provide the best solution. Beyond resolving current issues, we aim to help you prevent potential risks through professional services.

Additional Services

Additional services are value-added guarantees provided by Shenshi Technology beyond basic services. Shenshi Technology will use precise testing technology to comprehensively inspect equipment components and check for leakage risks. Based on the test results, we will offer suggestions for the best measures to help you resume production.

File Download

Product Manual

- Product catalog of coaxial tube/shell and tube heat exchangers

- Microchannel heat exchanger product sample