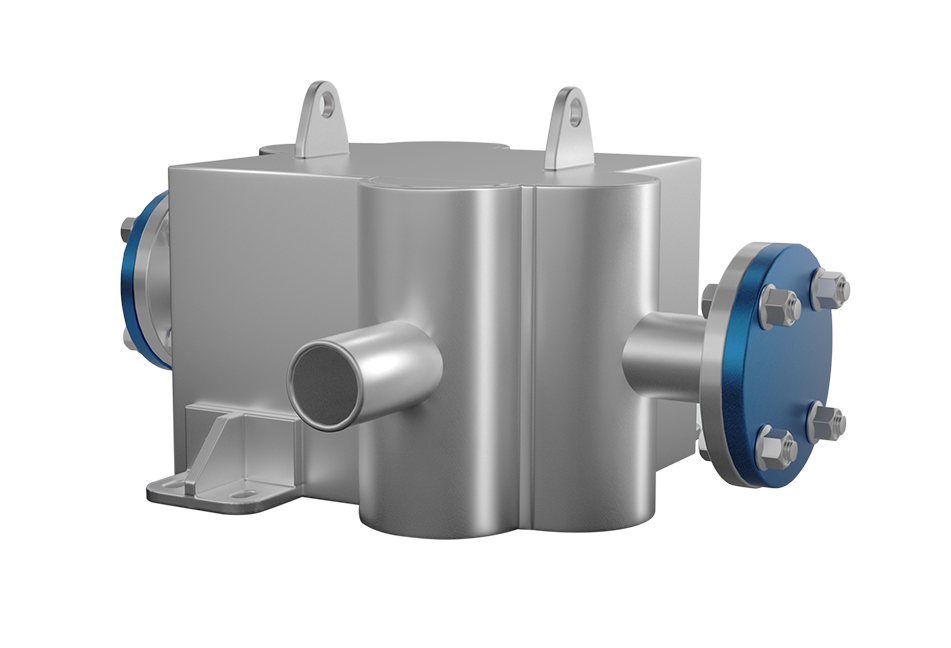

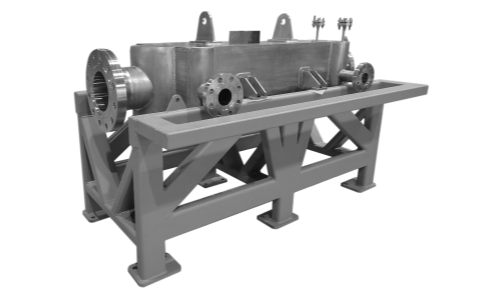

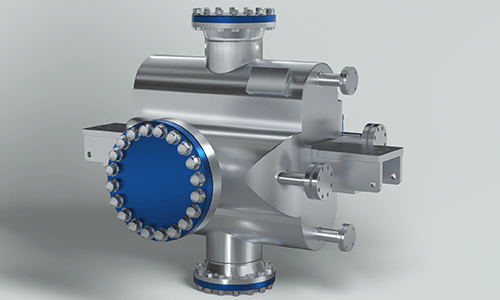

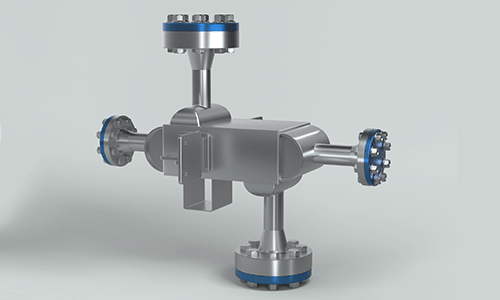

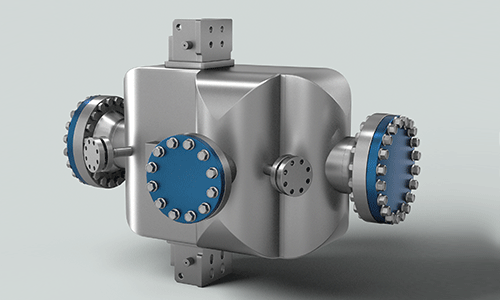

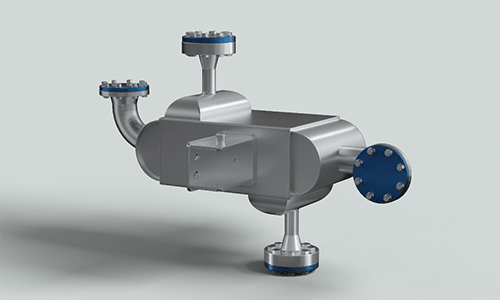

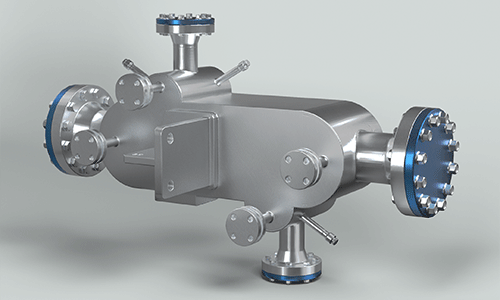

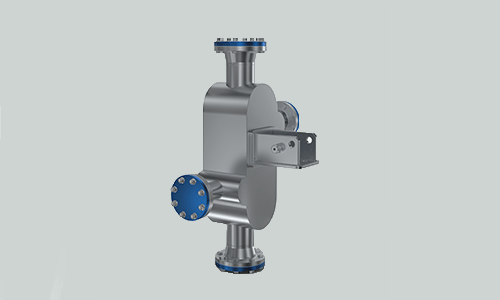

We specialize in designing and manufacturing high-performance printed circuit heat exchangers (PCHE), offering fully customized PCHE solutions and one-stop services for industrial clients worldwide.

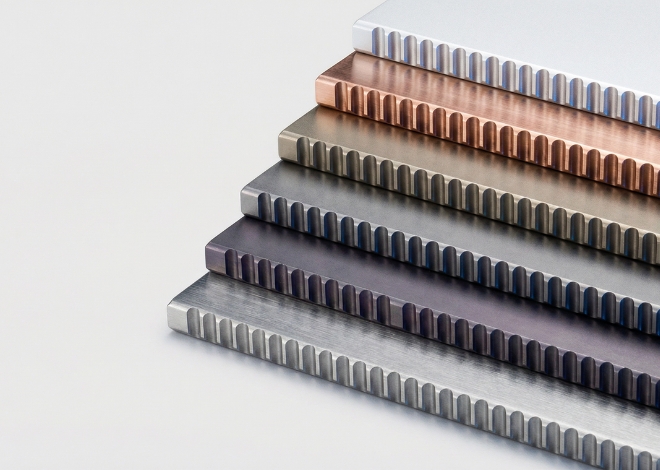

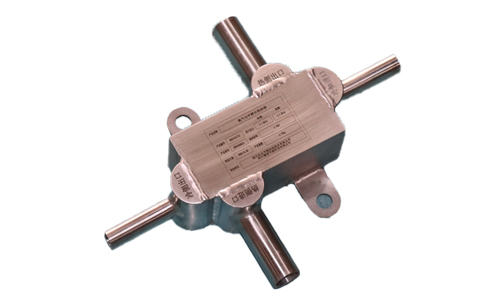

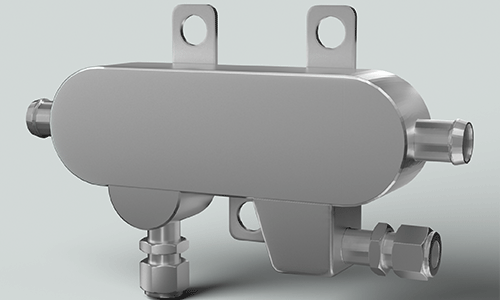

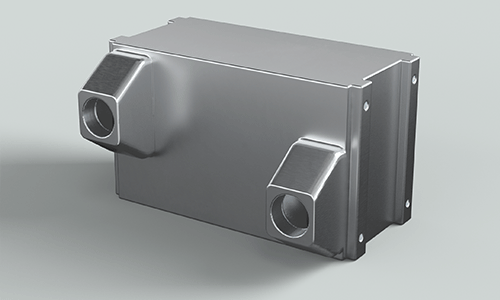

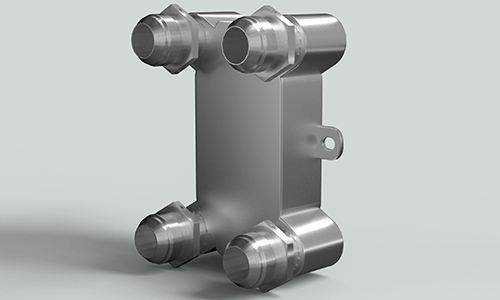

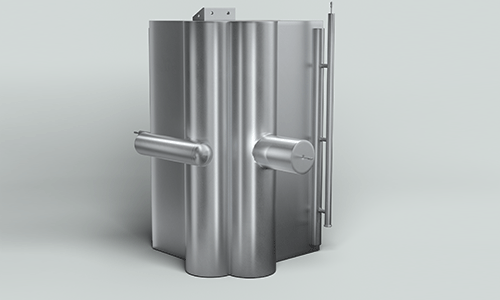

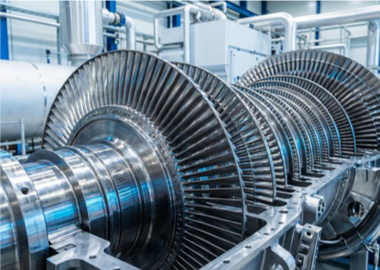

Our expertise lies in delivering tailor-made printed circuit heat exchangers that precisely match your operating conditions, fluids, pressure, and temperature requirements. Using advanced chemical etching technology, we produce microchannel cores with channel widths as fine as 0.2 mm and depths of 0.05 mm from premium materials including stainless steel, titanium, duplex steel, high-nickel alloys, and copper.

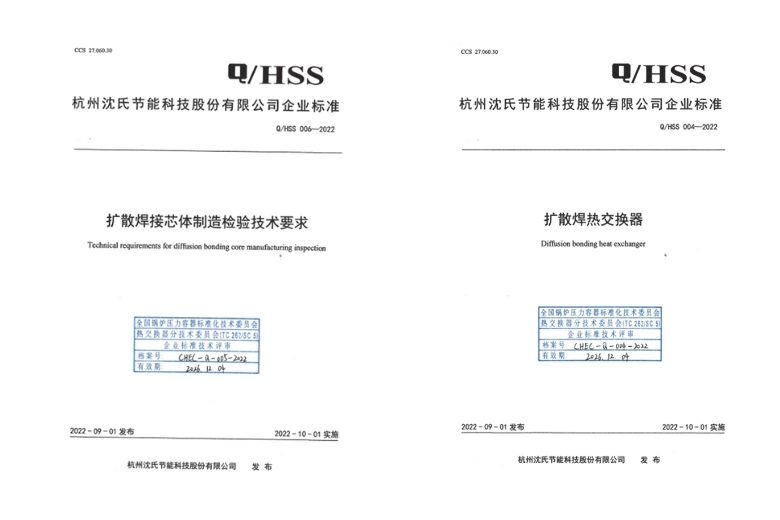

We provide comprehensive strength performance research (ASME/JB4732 compliant), flow properties study with ANSYS Fluent CFD, and full experimental verification to ensure maximum reliability and efficiency. Whether you need a diffusion bonded heat exchanger for supercritical CO₂, hydrogen, or high-pressure gas applications, our custom heat exchanger designs deliver superior compactness, safety, and energy efficiency.