Precision-Engineered Plate-fin Heat Exchangers (PFHE)

Leveraging state-of-the-art Vacuum Diffusion Welding, Shen’s PFHEs feature specialized fin structures designed for maximum heat exchange density and durability in harsh environments.

Engineered for longevity, our products offer Strong Corrosion Resistance to harsh substances including chlorine, acid, base, and mercury. This is a direct result of our deep expertise in material science and multi-industry knowledge.

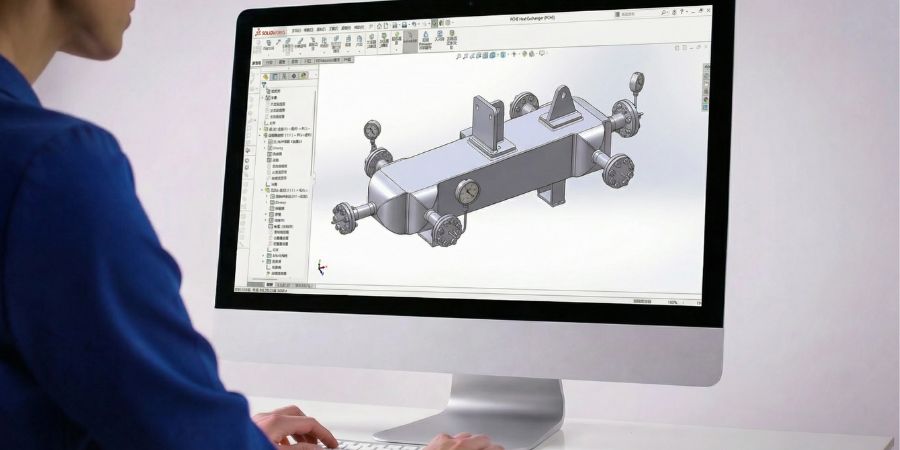

We provide unparalleled design flexibility by mastering a Wide Range of Materials, including titanium, stainless steel, superalloys, and copper alloys. This allows our experienced R&D team to create tailor-made solutions for your unique requirements.

We foster continuous improvement through an innovation ecosystem that includes deep cooperation with top-rank universities and customers. This agile and collaborative approach ensures we are always looking for better solutions in thermal energy.

Leveraging our R&D strength with 58+ patents, we engineer products that deliver reliable performance in the most demanding environments, withstanding extreme temperatures from -253°C to 1000°C and high pressures of 4-15MPa.

Our advanced manufacturing, featuring specialized diffusion welding, ensures High Reliability and structural integrity. This process, combined with state-of-the-art inspection, guarantees an exceptionally Low Leak Rate of 1*10-9Pa·m3/s.

With 20,000+ units deployed and certifications spanning from automotive to offshore, our solutions are field-proven. Our extensive industry experience ensures we can meet your exact budget, performance, and quality specifications.

Our industrial heat exchangers are constructed from high-grade materials, such as specialized aluminum alloys, creating a robust aluminum heat exchanger core through a vacuum brazing process. This results in a monolithic and durable brazed heat exchanger capable of withstanding demanding operational pressures and temperatures. The versatility of the design allows for various fin types and channel configurations, enabling us to tailor the heat exchanger performance to meet the specific requirements of any application, ensuring optimal efficiency and longevity.

The operational principle of a plate heat exchanger is elegantly simple yet highly effective. It facilitates the transfer of thermal energy between two or more fluid streams—one hot and one cold—without allowing them to mix. These fluids are directed into a network of alternating, sealed channels within the exchanger's core. The channels are separated by thin metal plates, to which corrugated fins are bonded. This sophisticated heat exchanger design dramatically increases the surface area available for heat exchange, enabling a high rate of heat transfer within a small volume and making it a leading example of a compact heat exchanger.

The process unfolds in a continuous, efficient cycle, typically arranged in a counterflow heat exchanger configuration to maximize thermal exchange. As the hot fluid flows through its channels, heat is transferred to the extensive surface of the fins and plates via convection. This energy then conducts rapidly through the highly conductive metal. On the other side of the plate, the cold fluid flows in the opposite direction, absorbing the heat from the plate surface, also through convection. This entire mechanism is governed by the heat transfer coefficient, which is maximized by the fin geometry, while maintaining a low pressure drop to ensure efficient fluid flow.

The fuel reformer mixes the fuel with water vapor, heats it, and feeds it into the anode of the system.

Heat is exchanged between water and high-temperature exhaust gases to produce a mixture of water vapor and fuel gas.

Reduce the temperature of CO₂ to its required operating range.

It is used to capture and utilize excess heat generated during the operation of nuclear power plants, helping to improve the overall efficiency of nuclear power plants.

The air heater is to heat the air that passes into the hydrogen production system to reach the reaction temperature.

The steam generator turns the raw water into a gas, which enters the SOEC reactor and produces hydrogen.

Hydrogen reformer produces hydrogen by reforming methanol, water and other fuels for heat exchange.

Hydrogen liquefaction plate-fin heat exchanger is a heat exchanger in which hydrogen and nitrogen gases are exchanged to cool them to liquid state

The hydrogen heater preheats the hydrogen that passes into the reactor, accelerates the start-up speed of the reactor, and then quickly starts the hydrogen fuel cell vehicle.

Effective control of cabin and electronic equipment temperature.

Ensure that the temperature of fuel and oil is stable and prevent overheating or undercooling from affecting engine performance and life.

Reduce the high temperature air temperature after supercharging to reduce the heat load of the engine and increase the power of the engine.

Our Plate Fin Heat Exchangers (PFHEs) are integral to advancing modern power generation. We provide critical thermal management solutions for high-performance systems, including Supercritical CO2 (sCO2) power generation, Solid Oxide Fuel Cell (SOFC) high-temperature systems, micro power generation units such as those in nuclear applications, and gas turbine power generation systems. Our PFHEs ensure maximum thermal efficiency and unparalleled reliability for a sustainable energy future.

In the burgeoning hydrogen economy, our Plate Fin Heat Exchangers (PFHEs) deliver precision temperature control essential for the entire value chain. From hydrogen production systems and hydrogenation machines to vehicle and fuel cell hydrogen supply systems, our technology ensures efficient and safe operations for production, storage, and distribution, accelerating the transition to clean hydrogen energy.

For demanding aerospace and aviation applications, our compact and lightweight Plate Fin Heat Exchangers (PFHEs) provide superior thermal management. They are essential for critical onboard systems, including environmental control systems (ECS) for cabin comfort, high-performance electronic (avionic) cooling systems, and robust oil cooling systems for engines, ensuring safety and reliability at any altitude.

Our Plate Fin Heat Exchangers (PFHEs) enhance the performance and efficiency of advanced engine systems. We deliver optimized cooling solutions for a range of applications, including high-performance powertrains, advanced liquid cooling systems, and powerful gas turbine power systems. Trust our PFHEs for robust, reliable, and efficient thermal management in marine, industrial, and power generation engines.

Learn More

Learn MoreWith 13,000 units deployed for automotive fuel cell hydrogen supply systems, Shenshi delivers high-performance plate fin heat exchanger solutions for clean energy applications.

Learn More

Learn MoreWith 30 units installed for 500KW merchant vessel diesel engines, Shenshi delivers compact plate fin heat exchanger solutions for marine engine cooling applications.

Learn More

Learn MoreFor Generation IV liquid metal reactors, Shenshi delivers custom high-temperature heat exchangers engineered for supercritical CO2 power cycles, enabling next-generation clean energy.

Gain complete peace of mind knowing your operations are safeguarded against unexpected downtime.

Shenshi creates a customized maintenance schedule tailored to your specific usage patterns, ensuring your heat exchanger remains reliable, efficient, and secure for the long haul.

Restore your equipment's peak performance with cleaning protocols designed specifically for your unique application.

Shenshi analyzes your system's condition to safely remove sediment and scale, giving you the confidence that your efficiency is maximized without compromising equipment integrity.

Experience the security of having a professional partner on standby, ready to protect your production continuity.

Shenshi's team doesn't just fix issues; we provide precise, personalized solutions that address the root cause, building a foundation of trust and long-term operational safety for your business.

Go beyond basic service with our precision testing and leakage risk assessments, designed to give you absolute certainty.

Shenshi provides data-driven advice and advanced inspections, ensuring you can resume production with full confidence in your equipment's safety and reliability.