ShenShi Microchemical Solutions for Fine Chemicals

Advanced

Microchemical Solutions

Compact design reduces volume by 50%

Corrosion-resistant materials: 316L, Hastelloy, Sic

Precise control with partitioned temperature zones

Our compact, efficient systems support continuous flow processes,ensuring safety and sustainability.

Related Applications

Agrochemicals

Synthesis efficiency-automate and reduce costs.

Pharmaceuticals

Drug synthesis, catalysis, purification boost R&D.

Petrochemicals

Heavy oil cracking enables continuous, cost-effective output.

Dyes & Pigments

Uniform mixing enhance continuity and innovation.

Related products

- Microchannel Reactor

Integrates multiple microchannel reaction units into a compact reaction device.

Spiral Tube ReactorAchieves efficient mixing and heat transfer through the rotating flow inside the spiral tube.

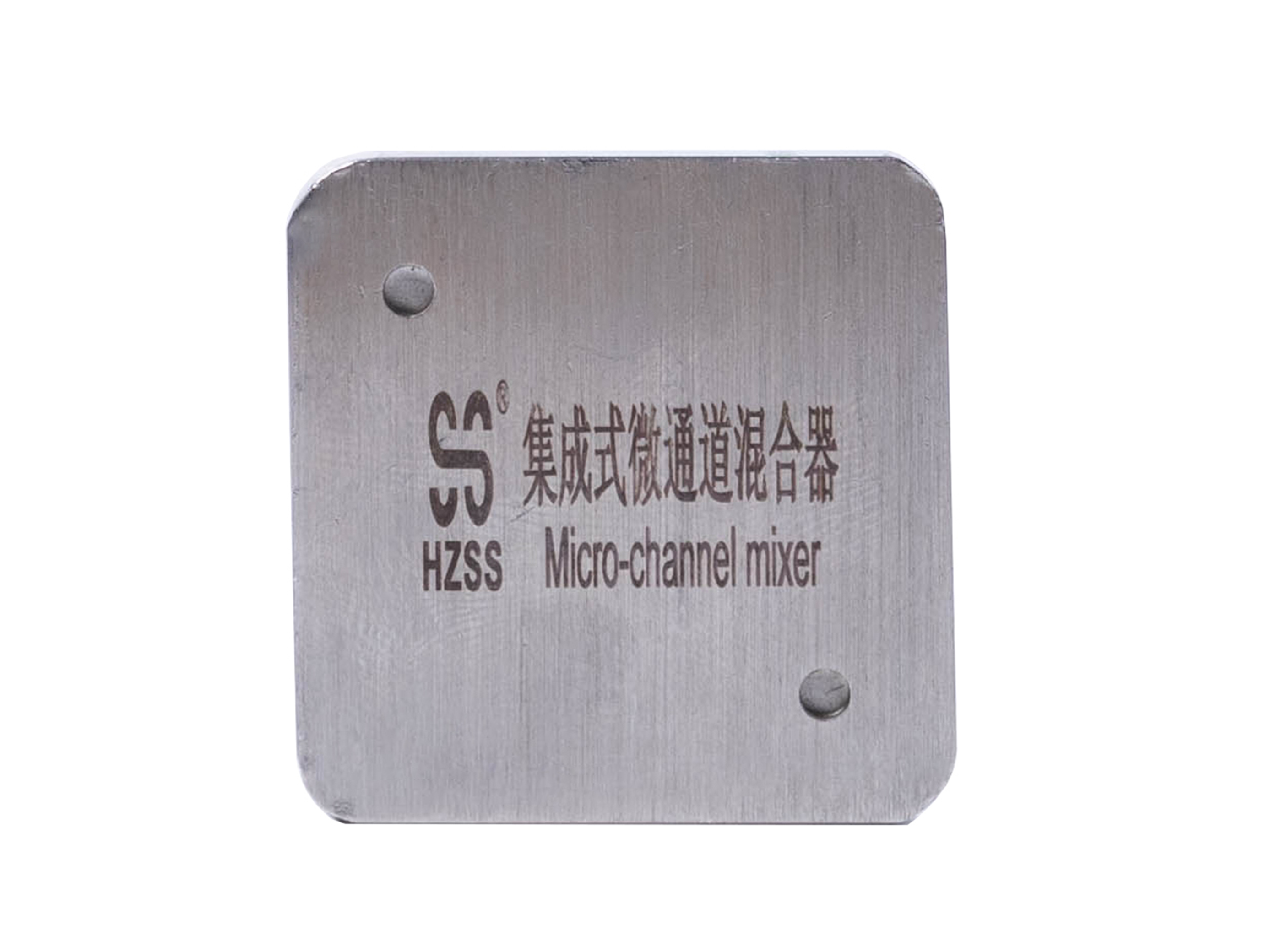

Microchannel MixerUtilizes fluid dynamics effects within microchannels to achieve rapid and uniform mixing.

Laboratory-Scale ReactorA miniaturized reaction device suitable for laboratory research.

Micro Continuous Flow Skid SystemAn integrated reaction device combining microreaction technology with continuous flow technology.

Case story: Continuous Hydrogenation, Chlorination, Extraction, and Quenching Project for a Pharmaceutical CDMO Enterprise

The project is designed with an annual capacity of 300 tons. in traditional batch reactors, long reaction times and multiple by-products create significant safety risks. By adopting a continuous flow process, the complex steps of chlorination, hydrogenation, extraction, and quenching are integrated into one streamlined and automated system, improving both production efficiency and safety.

Challenges with previous approach:•Extended reaction times in batch reactors leading to excessive by-products

•Complicated multi-step process with high safety risks

•Large equipment footprint and complex manual operations.

•Low level of automation and limited process control

Optimized features with continuous process:

✔Continuous flow technology ensures more stable reactions and fewer by-products

✔High level of automation (over 2,600 functional units with only 5 operation points)

✔Compact equipment footprint with continuous, efficient operation

✔Simplified operation and significantly improved safety

Case story: Continuous Microreactor System for Yangnong Chemical Ningxia-Pesticide Intermediate Production

The project was delivered in April 2018 with an annual throughput of 18,000 tons of pesticide intermediates. The original production line of jiangsu Yangnong Chemical had a capacity of 7,000 tons per year, occupying about 150㎡ land area with 300㎡ building area. The workshop required a three-story structure with a total height of 18 meters.

Challenges with previous approach:•Large plant footprint with complex multi-story workshop requirements

•Long batch reaction times, limiting production efficiency

•Harsh operating conditions, including low reaction temperature (-15°C)

•High wastewater discharge, creating environmental pressure

Optimized features with continuous process:✔Reduced footprint to 23㎡, eliminating the need for multi-story structures

✔Continuous reaction time shortened to 1/1000 of the original

✔Wastewater reduced to 4.3% of the original level, supporting green production

✔Yield increased by 6-8%, fundamentally transforming the original process conditions

✔Reaction temperature improved from -15'c to 40°c, expanding operating flexibility

Comprehensive Service Support

Product Upgrade

Upgrade existing products with latest technology to boost efficiency and extend service life.

Service Support

One-year warranty with free replacement for any product quality issues.

Expert Assistance

24/7 professional response ensures quick solutions and risk prevention.

- *Name

- *Phone

- *Title

- *Content

Download

Product Introduction

- Microcontinuous flow product sample