Transfer heat between compressor terminal exhaust and refrigerant to liquefy the gas.

Reliquefaction System

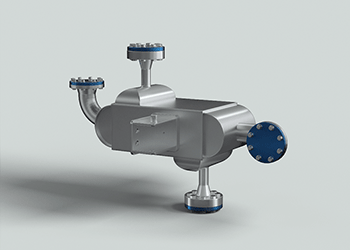

The reliquefaction of industrial gases—such as ethane, ammonia, and LNG—is essential for efficient transport and storage due to their high boiling points. A typical reliquefaction system includes several key components: a compressor to raise gas pressure above its liquefaction point; coolers to reduce gas temperature below this point; a pressure reducing valve to regulate pressure; separators to isolate liquefied gas from residual vapor; and storage tanks to safely hold the liquid gas for future use. This process ensures efficient gas management in industrial operations and supports safe, stable supply chains.

Home / Reliquefaction system

Reliquefaction Solutions

Shen Technology provides thermal management solutions for reliquefaction systems, intercoolers for compressors, liquefaction heat exchangers and economizers for cooling systems, and carburetors for back-end applications.

Related Products

- Carburetor

When gas is needed, it is heated to vaporize, such as LNG carburetor, ammonia carburetor, etc.

Related Industry

Suitable for liquefying industrial gases such as hydrogen, LNG, propane, and ammonia for convenient transportation.

During the gasification of liquids, a significant amount of cold energy is released. Shen's Technology heat exchangers can use this energy to produce other gas products or generate electricity.

At hydrogen refueling stations, hydrogen compressors compress hydrogen to tens of MPa for storage. Heat exchangers cool the high temperatures generated by the compressors to ensure safety.

File Download

Product Manual

- Microchannel Heat Exchanger Product Sample