What type of heat exchanger is PCHE?

A Printed Circuit Heat Exchanger (PCHE), also known as a Diffusion-Bonded Compact Heat Exchanger (DCHE), represents the pinnacle of thermal engineering and is a core technology in Shenshi's advanced product lineup. It is a revolutionary type of heat exchanger fabricated using principles akin to 3D printing and chemical etching, resulting in an unparalleled combination of power, resilience, and compactness.

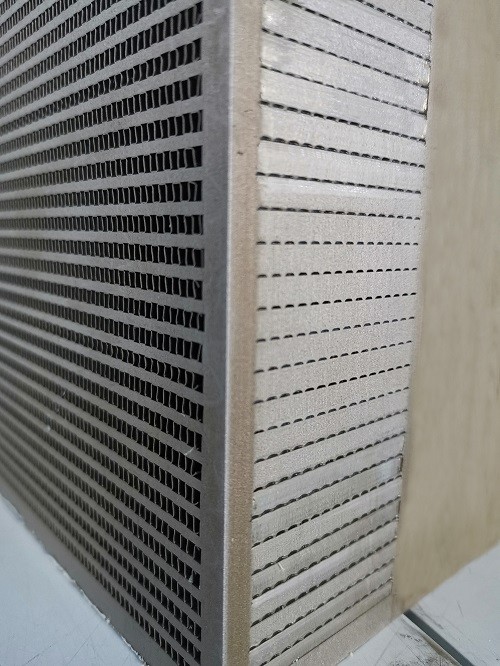

So, what exactly is a PCHE? It is a highly sophisticated device constructed by chemically etching intricate, semi-circular flow channels into multiple metal plates—with channel dimensions precision-engineered on a scale from micrometers to millimeters. These etched plates are then meticulously aligned and fused together through a solid-state diffusion bonding process under high temperature and pressure. This creates a single, monolithic, and incredibly strong core block with no mechanical joints, braze points, or gaskets, which are common failure points in traditional exchangers.

The defining characteristic of the PCHE is its extraordinary compactness. It achieves a heat transfer surface area per unit volume that is orders of magnitude greater than that of shell-and-tube or even plate-and-frame heat exchangers. This means it can handle massive thermal duties in a fraction of the physical space, making it indispensable where footprint and weight are critical constraints.

Furthermore, its diffusion-bonded construction allows it to operate reliably under extreme conditions that would destroy conventional exchangers, including temperatures ranging from cryogenic to over 900°C and pressures exceeding 600 bar. Different fluids—such as helium, natural gas, supercritical carbon dioxide (SCO₂), water, and air—can flow through adjacent layers of channels, enabling highly efficient heat exchange between them.

This combination of a massive surface area, excellent material strength, and the turbulent flow in its micro-channels gives the PCHE exceptional heat transfer performance and efficiency. It is the technology of choice for the most demanding applications across industries, including:

LNG & FLNG: As main cryogenic heat exchangers for natural gas liquefaction.

Nuclear Power: In next-generation reactors like High-Temperature Gas-Cooled Reactors (HTGRs).

Supercritical CO₂ Power Cycles: As heaters and recuperators in highly efficient closed-loop systems.

Aerospace & Defense: For thermal management in avionics and propulsion systems.

Hydrogen Energy: For liquefaction and storage processes.