What is the working principle of the Hydrogen Precooler?

What is the working principle of the Hydrogen Precooler?

The hydrogen pre-cooler developed by Shenshi can be applied to hydrogen refueling stations. Its advantages of explosion-proof, anti-freezing, and low temperature are the perfect solution to improve the reliability and advancement of hydrogen refueling stations in the future.

The working principle of hydrogen precooler:

The volume expansion of high-pressure hydrogen after being filled into the hydrogen cylinder will release heat, which will cause the temperature in the hydrogen cylinder to rise. The higher the hydrogen filling rate, the faster the temperature of the hydrogen cylinder will rise. Due to the material of the hydrogen cylinder, etc. The internal temperature of the hydrogen cylinder must not exceed 85°C during use. Therefore, in order to ensure the hydrogen filling rate, the hydrogen must be pre-cooled before the hydrogen filling. Commonly used hydrogenation machines are divided into 70MPa and 35MPa. The 35MPa hydrogen precooler is suitable for 35MPa hydrogenation machines.

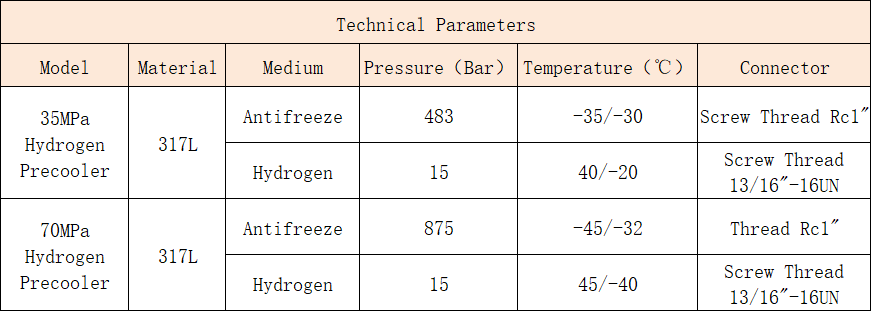

Hydrogen-antifreeze heat exchange microchannel heat exchanger for hydrogen energy hydrogenation machine (corresponding to 35MPa and 70MPa hydrogenation machines):

- Small size and light weight can be integrated inside the hydrogenation machine:

The dimensions of the 35MPa hydrogen cooler are 400*250*170mm;

The outline dimension of the 70MPa hydrogen cooler is 400*250*220mm.

- Corresponding to various filling stations (online hydrogen production type, external hydrogen supply type, etc.):

35MPa hydrogen cooler working temperature -20~45℃;

35MPa hydrogen cooler working temperature -40~45℃.

- Hydrogen cooling for single or double gun models can be provided:

35MPa model use pressure 48.3MPa (max);

The 70MPa model uses a pressure of 99MPa (max).