From Ethane Transportation to a Zero-Carbon Future: Breaking the Monopoly, Chinese Shipbuilders Secure 70% of Global Orders

Ethane, as a high-quality raw material for ethylene production, features lightness and low carbon content, which are highly consistent with the emission reduction demands of the petrochemical industry. The ethane-to-ethylene process, with its advantages of short process flow, low energy consumption, and high ethylene yield, has seen a continuous increase in its capacity share.

Meanwhile, the long-distance transportation demand for ethane feedstock has driven technological breakthroughs and market expansion of very large ethane carriers (VLECs). It is expected that the operational fleet (including ultra large ethane carriers, ULECs) will exceed 70 vessels by 2027. Chinese shipbuilding enterprises are transforming from "followers" to "leaders" in this field.

I. VLEC: The "Super Carrier" for Ethane Transportation

II. Development Trends of VLEC

The independent development of the "BrilliancE®" B-type tank technology by Jiangnan Shipyard has broken the international monopoly and brought China's VLEC design and construction capabilities to the forefront of the global industry. As of 2024, Jiangnan Shipyard's VLEC fleet accounts for 80.2% of the global market share by capacity, firmly holding the top position in the industry and achieving a "double crush" over South Korean shipyards in terms of both technology and cost. Private enterprises such as Yangzijiang Shipbuilding have entered the market through technology cooperation, forming an industrial pattern of "state-owned enterprises leading and private enterprises collaborating".

2. Green Shipping Forces Energy Efficiency Upgrades

The International Maritime Organization (IMO) aims for the shipping industry to achieve net-zero emissions by 2050, and the European Union's Carbon Border Adjustment Mechanism (CBAM) strengthens emission reduction requirements, compelling shipowners to adopt ultra-low energy consumption designs. Jiangnan Shipyard's VLEC features reliability, energy efficiency, and environmental friendliness, with comprehensive economic performance indicators reaching international advanced levels. Additionally, its B-type tanks can also be compatible with the transportation of various gases such as ethylene and LPG, and may extend to zero-carbon fuels such as liquid ammonia in the future.

III. Invisible Escort: Energy Efficiency Optimization Thermal Management

The energy efficiency improvement of VLEC is fully integrated with low-carbon technologies, such as reducing the emission of evaporation gas through the reliquefaction system, among which thermal management is one of the key links.

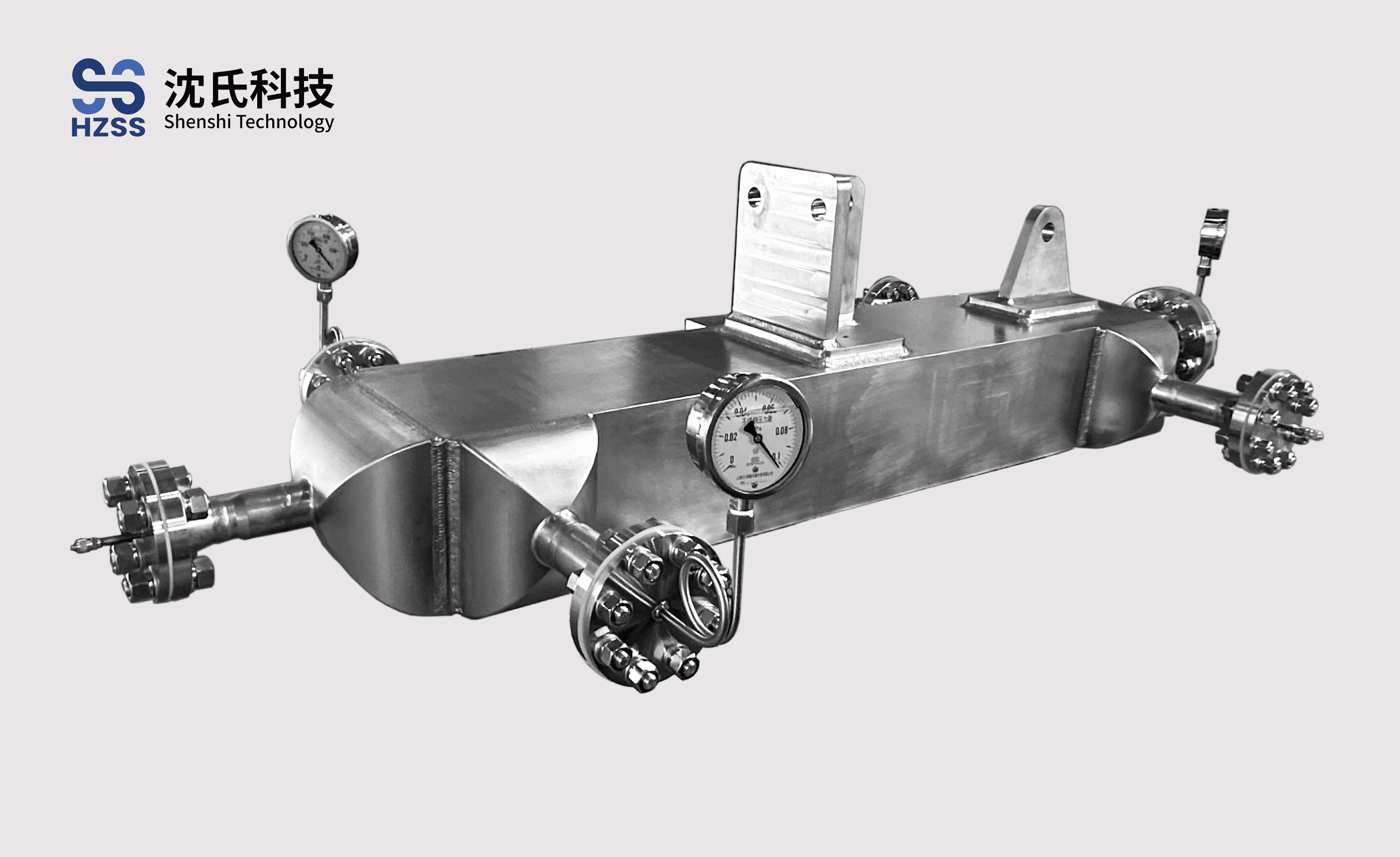

Taking Jiangnan Shipyard's VLEC as an example, Babcock LGE, a global leader in the field of ship liquefied gas systems, has customized the ecoETHN® integrated solution for Jiangnan Shipyard's 15 98,000 m³ VLEC vessels. In this project, in the face of the cryogenic transportation environment and strict energy efficiency standards, Shenshi Technology, with its professional thermal management solutions, has become the key heat exchanger (PCHE) supplier for the Babcock LGE ecoETHN® reliquefaction system.

The PCHE fabricated by diffusion welding technology reduces its volume to 1/6 of the traditional solution through precise channel design, which frees up cargo space to generate additional revenue. Moreover, its heat exchange efficiency is significantly enhanced, and the evaporation loss of the system is reduced.

With the growth of global ethane transportation demand and the increasing requirements for ship economic efficiency, VLEC is becoming the "new favorite" of shipowners. Chinese shipbuilding enterprises, relying on their independent innovation and production capacity advantages, are expected to further consolidate their global leading position. Meanwhile, the wide application of B-type tanks will drive VLEC to evolve towards larger, more efficient and more environmentally friendly directions. At the same time, changes in the international energy trade pattern and emerging market demands such as chemical projects in Southeast Asia will provide continuous growth momentum for VLEC.