What are Supercritical CO2 Power Cycles?

As the world moves towards the goal of carbon neutrality, the energy structure is accelerating its shift towards low-carbon and clean energy. Against this backdrop, ShenShi Technology adheres to the mission of "Integrating Wisdom and Innovation, Ecological Technology", deeply integrating the concept of sustainable development into technological research and development, and is committed to reducing carbon emissions and resource consumption in the energy production process, promoting a green future.

For this reason, ShenShi Technology has continuously devoted efforts to in-depth research on the supercritical carbon dioxide power cycle system and its core component - the heat exchanger. The supercritical carbon dioxide power cycle is a promising low-carbon and environmentally friendly power generation technology that can effectively enhance the utilization rate of traditional energy sources, reduce emissions, and be compatible with clean energy sources such as solar, geothermal, and nuclear energy.

What are supercritical CO2 Power Cycles?

Maybe you already heard about the term supercritical CO2 powercycle,or sCO2 Brayton Cycle. lt shows similarities with a steampower cycle, but the driving fluid is not water (steam) but CO2. Theinstallations are expected to be a lot lower in cost, while also theefficiency will be much higher. lt has therefore attracted a lot of attention in the power industry and various research organizations are investigating and developing these power cycles.

The sCO2 Brayton cycle is also scalable and can be applied to mostthermal sources, making it versatile for various applications including nuclear, solar thermal, geothermal, and fossil fuel powerproduction.

In this article l will first explain a bit more what supercritical CO2 powercycle are.Then we will go into a couple of applications of these power cycles.

Supercritical CO2 power cycles utilize carbon dioxide in asupercritical state, where it is above its critical temperature and pressure, making it neither a distinct liquid nor gas. This state allow sC02 to exhibit properties that are advantageous for power generation. In contrast to traditional steam cycles that use water or steam as the working fluid, supercritical CO2 cycles operate with CO2, which has a lower critical pressure and a higher density thansteam. This results in a more compact system with smaller components, potentially reducing capital costs and plant footprint.

For CO2 the critical temperature (304.128 K,30.9780℃,87.7604℉) and the critical pressure (7.3773 MPa, 72.808 atm,1,070.0 psi, 73.773 bar)

The efficiency of supercritical CO2 (sCO2) Brayton cycles is generally higher than that of traditional steam-based power cycles. The sCO2 Brayton cycle can achieve thermal efficiencies of over 45%,depending on the cycle configuration, compared to around 35% for high-temperature steam Rankine systems.

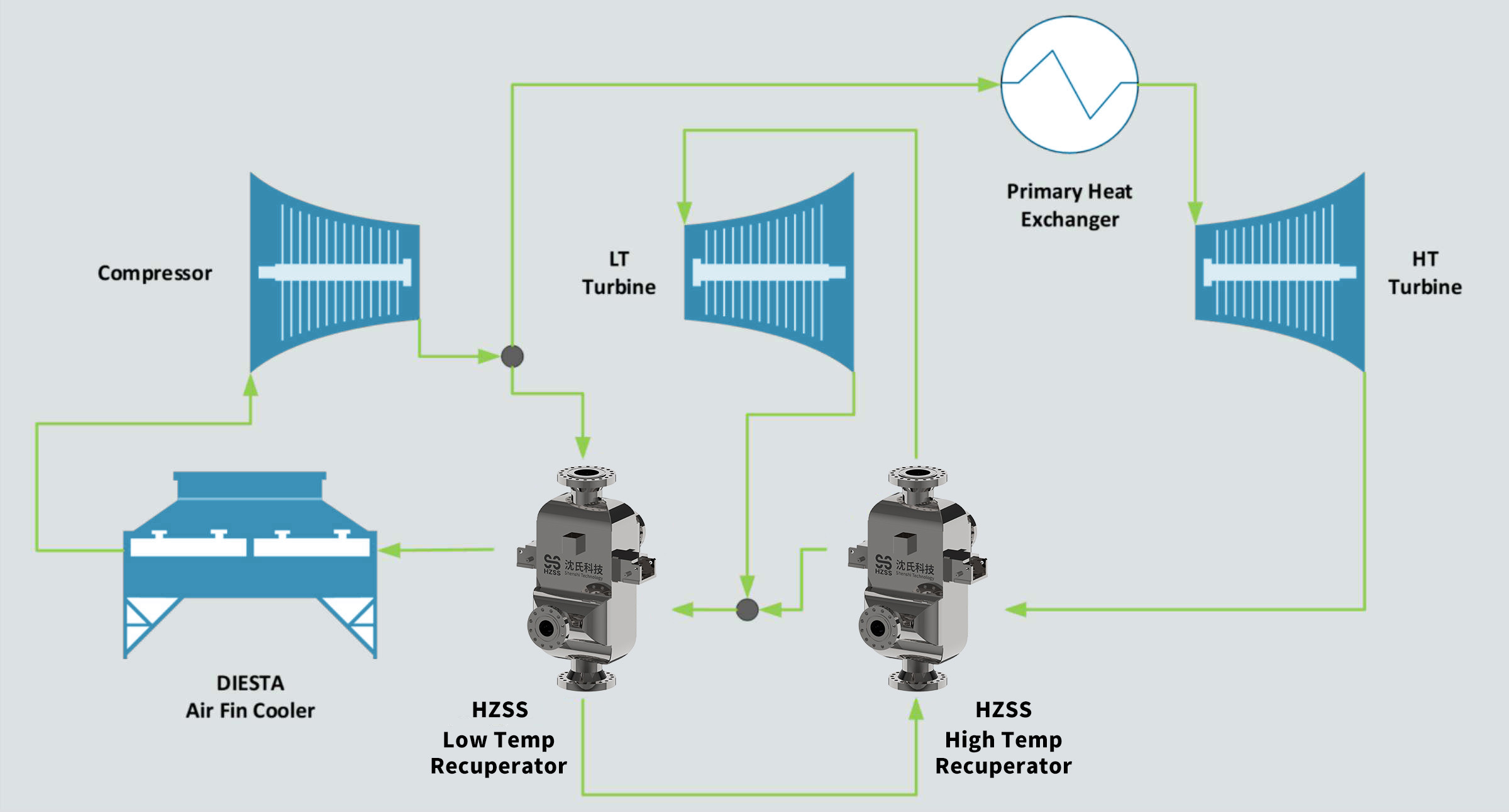

Similar to other power cycles, a sCO2 power cycle needs a heatsource. The heat is put into the system by the Primary Heat Exchanger. The heat exchanger type selection will depend on the source of the heat. This can for instance be waste heat from flue gas hat would ask for a tube bundle in a flue gas duct. But it can also be heat in molten salt that comes from concentrated solar power or from a nuclear reactor. In that case a printed circuit heat exchanger(PCHE) would be the right choice. In the power cycle there will be recuperators to exchanger heat between sCO2 and sCO2 between the different turbine sections in order to improve efficiency.

The cycle also needs to dissipate heat to a heatsink. Here the mainchoice will be between cooling against ambient air (dry cooling) orby using cooling water. One study looking into cooling options for sCO2 cycles pointed out that "one of the key advantages of sCO2 systems relative to competing steam Rankine cycles is theelimination of water usage from the power cycle". And this advocates for the use of dry cooling.

Figure 1: Flow diagram sCO2 power cycle (Brayton Cycle)

Examples of research projects and applications using sCO2 power cycles

In this section we will look into some example applications and research projects in which sCO2 power cycles are or can be used.This is the best way to illustrate the principle.

1.Supercritical CO2 Transformational Electric Power(STEP) Pilot Plant

The STEP pilot plant in the United States is a significant investment.It aims to validate sCO2-based power generation, achieve higherefficiency, reduce costs, and lower emissions. The project involvespublic-private partnerships and demonstrates the potential of sCO2technology across various applications.

GTl Energy leads this $159 million government/industry partnershipteaming with Southwest Research Institute, GE Research, and the USDOE National Energy Technology Laboratory.

2.CARBOSOLA project Helmholtz-ZentrumDresden-Rossendorf

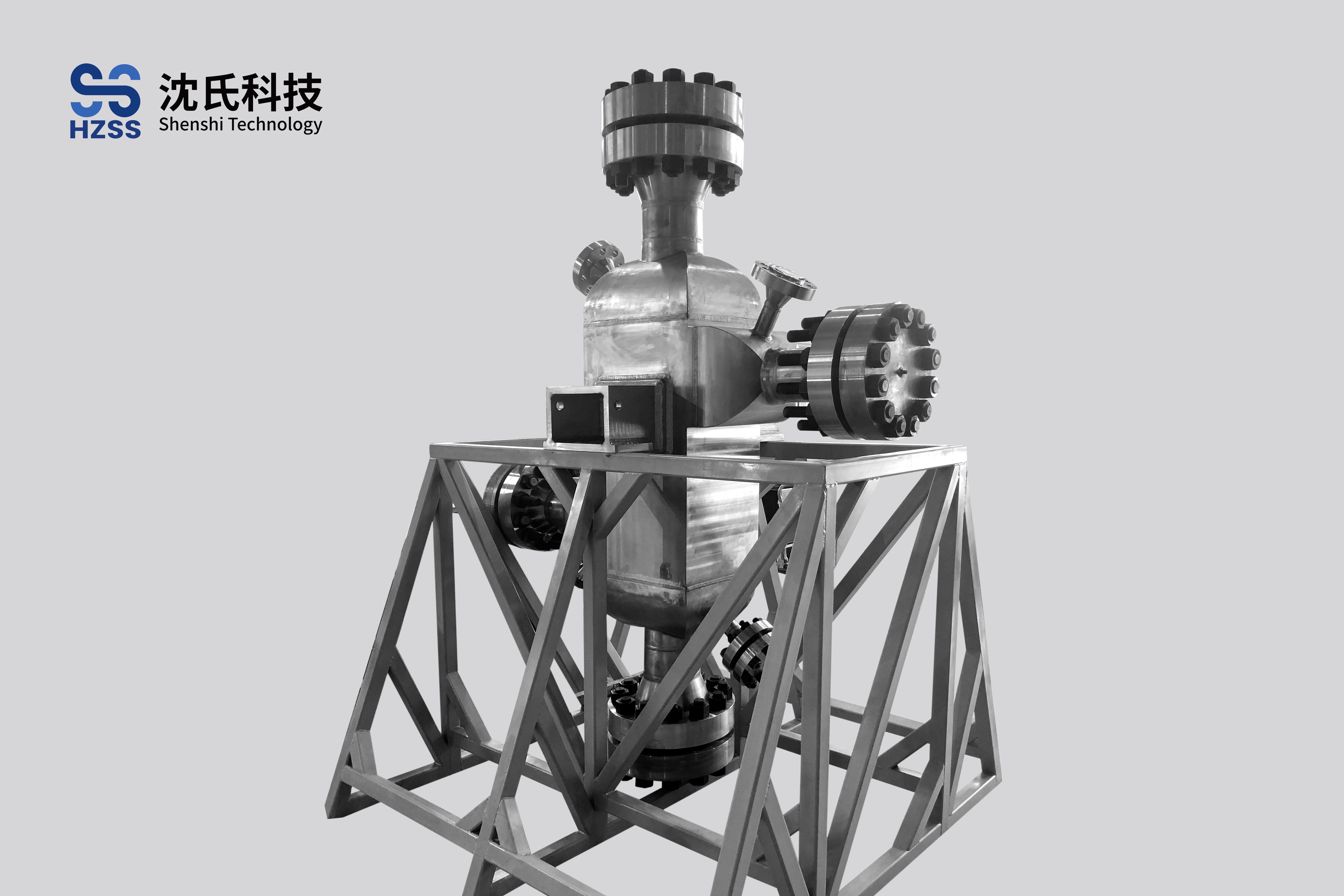

"In the frame of the CARBOSOLA project the design and commissioning of an operating technical scale facility with sCO2 as aworking fluid was performed at the Helmholtz-Zentrum Dresden-Rossendorf Temperatures up to 520 'C at 300 bar and mass flowrates of 1.32 kg/s are possible".

Figure 2: ShenShi printed circuit heat exchanger recuperator in Helmholtz Dresden

3. Turning waste heat from Gas Turbine intoelectricity

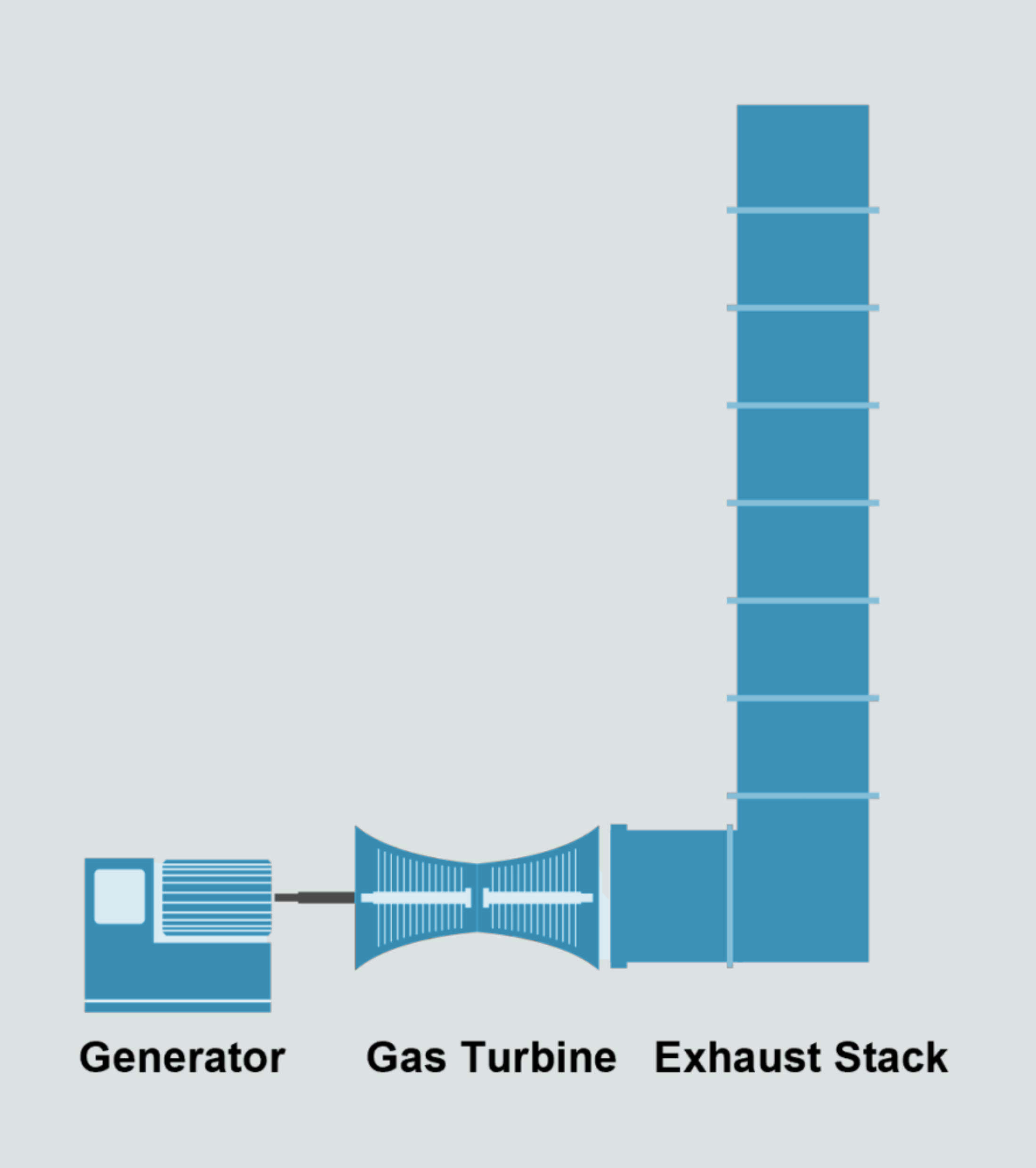

Remote oil & gas location often use simple cycle gas turbines. At thetime that they were installed the energy efficiency was not of high priority. Nevertheless, hot flue gasses are leaving the gas turbinestack into the atmosphere and valuable heat is wasted. instead, this heat could be captured with a heat recovery unit and be fed into a sCO2 power cycle.

Fig 3: Simple cycle gas turbine

Existing installations can be upgraded by removing the old stack and install a bypass stack and a heat recover system. The heat recovery system contains tube bundles through which the CO2 flows and is heated by means of the flue gasses.

Fig 4: sCO2 power cycle heat recovery after gas turbine

4. Allam-Fetvedt Cycle zero emission power generation

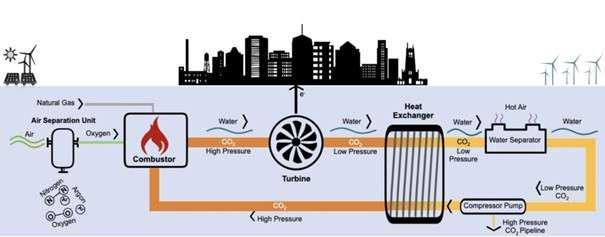

A quite special type of sCO2 power cycle is the Allam-Fetvedt Cycle(AFC). In this cycle, natural gas is burned with pure oxygen. The high-pressure exhaust from the combustor is supplied to a turbineexpander, and upon leaving the expander, the mixture is cooled,allowing liquid water to be removed. The nearly pure CO2 working fluid then enters a compression and pumping stage, preparing it forrecirculation. This process is designed such that nearly all the CO2 iscaptured to great (almost) zero emission power.

One company commercially developing this power cycle is NET Power in US."The company's oxy-combustion supercritical carbondioxide power cycle was successfully proven at its demonstrationplant in La Porte, Texas-a 50-MW pilot completed by contractor McDermott Intemational in 2021 and successfully synchronized with the Texas grid after operating for more than 1,500 hours" .

NET Power is now developing the first commercial plant in Odessa,Texas which shall be operational by 2027

Fig 5: NET Power Allam-Fetvedt power cycle (courtesy Power Magazine)

Clearly there is a lot of activity in the field of supercritical CO2 cycles, Many research intitutes are working on it and there are evencommercial scale projects under development utilizing sCO2 powercycles.

Given the fact that these power cycles are more efficient and lowerin investment it is expected that this technology will be broadly adopted by the power industry.

The growth of sCO2 power cycles can further be accerated as it works well with new energies such as:

·concentrated solar power

·geothermal power

·nuclear power