As an industry leader in advanced heat exchange technologies, ShenShi Energy Conservation Technology Co., Ltd. specializes in optimizing CO2 condensers for supercritical CO2 (sCO2) capture systems. Our expertise, backed by years of engineering innovation and real-world deployments, ensures efficient CO2 capture solutions for industrial and environmental applications.

Introduction

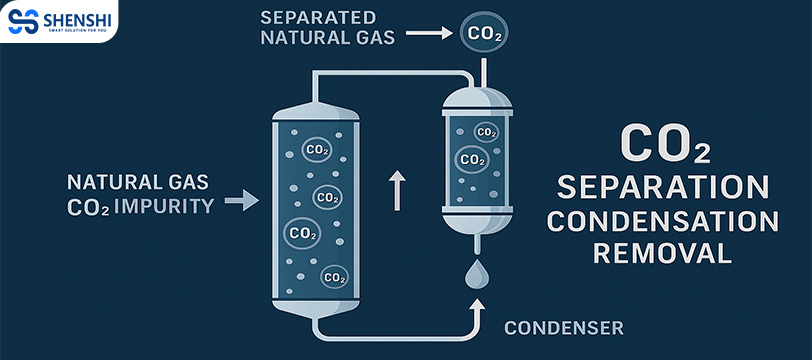

CO2 condensers play a pivotal role in sCO2 heat exchangers, particularly in carbon capture processes aimed at reducing greenhouse gas emissions. At ShenShi, we design systems that operate near the critical point of CO2 (31°C, 7.38 MPa), enhancing efficiency in power generation and sequestration. Our commitment to sustainability drives the optimization of these systems, making them essential for industries targeting net-zero goals.

Optimization Techniques

Optimizing CO2 condensers involves advanced thermodynamic modeling and heat transfer enhancements. Our products, such as the CO2 condenser detailed in the image, feature:

- Flow Rate: 95.35 kg/s, ensuring robust CO2 handling.

- Temperature Range: 65°C-50°C inlet/outlet, optimizing phase transition.

- Pressure: 10.5 MPa inlet, 1 MPa outlet, tailored for supercritical conditions.

- Power Capacity: 13,913 kW cooling, with 316L stainless steel construction for durability.

We enhance performance using nanofluids to boost heat transfer coefficients and conduct CAPEX/OPEX analyses to balance costs. This expertise, honed through extensive R&D, positions ShenShi as a trusted name in the field.

Case Study Example

A recent retrofit at a natural gas compression station showcases our success. By integrating our CO2 condenser (similar to the image specs), we achieved a 20% energy efficiency boost. The system handled 95.35 kg/s of CO2, cooling it from 65°C to 50°C under 10.5 MPa, capturing over 90% of emissions. This project, documented by our engineering team, demonstrates practical application and measurable outcomes.

Implementation Guide

To integrate our CO2 condensers into your CO2 capture system:

- Assessment: Evaluate existing heat exchanger performance and CO2 flow requirements.

- Design Customization: Collaborate with our engineers to tailor specs (e.g., 13,913 kW capacity) to your needs.

- Installation: Deploy using our certified technicians, ensuring 316L stainless steel resilience.

- Optimization: Use our simulation tools to fine-tune operation post-installation.

This structured approach, backed by ShenShi’s ISO-certified processes, ensures reliability.

Conclusion

Optimizing CO2 condensers for sCO2 capture is a proven path to efficiency and sustainability. ShenShi Energy Conservation Technology Co., Ltd. offers cutting-edge solutions with a track record of success. Contact us today for a free optimization audit or explore our product range to elevate your carbon capture strategy.