Shell and Tube Exchanger Efficiency Tips

Why Efficiency Matters

Efficiency is key to reducing energy costs. A drop in performance can increase operational expenses by up to 40%. SHENSHI’s advanced manufacturing, backed by a 44,000 m² production base, ensures high-quality shell and tube exchangers. Our focus on sustainability aligns with China’s “dual carbon” goals. Let’s dive into practical ways to maintain peak efficiency.

Impact of Inefficiency

- Higher energy consumption.

- Increased maintenance costs.

- Reduced equipment lifespan.

Top 5 Efficiency Tips for Shell and Tube Exchangers

1. Optimize Flow Conditions

Proper flow enhances heat transfer. Countercurrent flow, where fluids move in opposite directions, can improve efficiency by 15%. SHENSHI’s engineers design systems with this principle, as seen in our marine and offshore applications.

- Action: Use CFD tools to adjust flow rates.

- Benefit: Maximizes heat exchange.

- SHENSHI Edge: Our shell and tube exchangers feature optimized designs for diverse industries.

2. Prevent and Manage Fouling

Fouling reduces heat transfer over time. Regular cleaning restores performance. SHENSHI’s R&D, with over 100 patents, includes fouling-resistant technologies used in refrigeration and hydrogen energy sectors.

- Action: Schedule chemical cleaning every six months.

- Benefit: Prevents efficiency loss.

- SHENSHI Edge: Our PCHE microchannel heat exchangers resist fouling effectively.

3. Upgrade Materials for Durability

Material choice affects efficiency. Stainless steel or titanium resists corrosion, ideal for harsh environments. SHENSHI’s ASME-certified production delivers durable solutions, as proven in our aerospace thermal control projects.

- Action: Assess fluid compatibility.

- Benefit: Enhances longevity.

- SHENSHI Edge: Custom material options available.

4. Implement Routine Maintenance

Regular checks prevent efficiency drops. SHENSHI’s maintenance tips include inspecting gaskets and fluids, drawing from our 20-year expertise. Our Zhejiang Provincial Research Institute supports these innovations.

- Action: Conduct annual inspections.

- Benefit: Extends equipment life.

- SHENSHI Edge: ISO9001:2015-certified quality assurance.

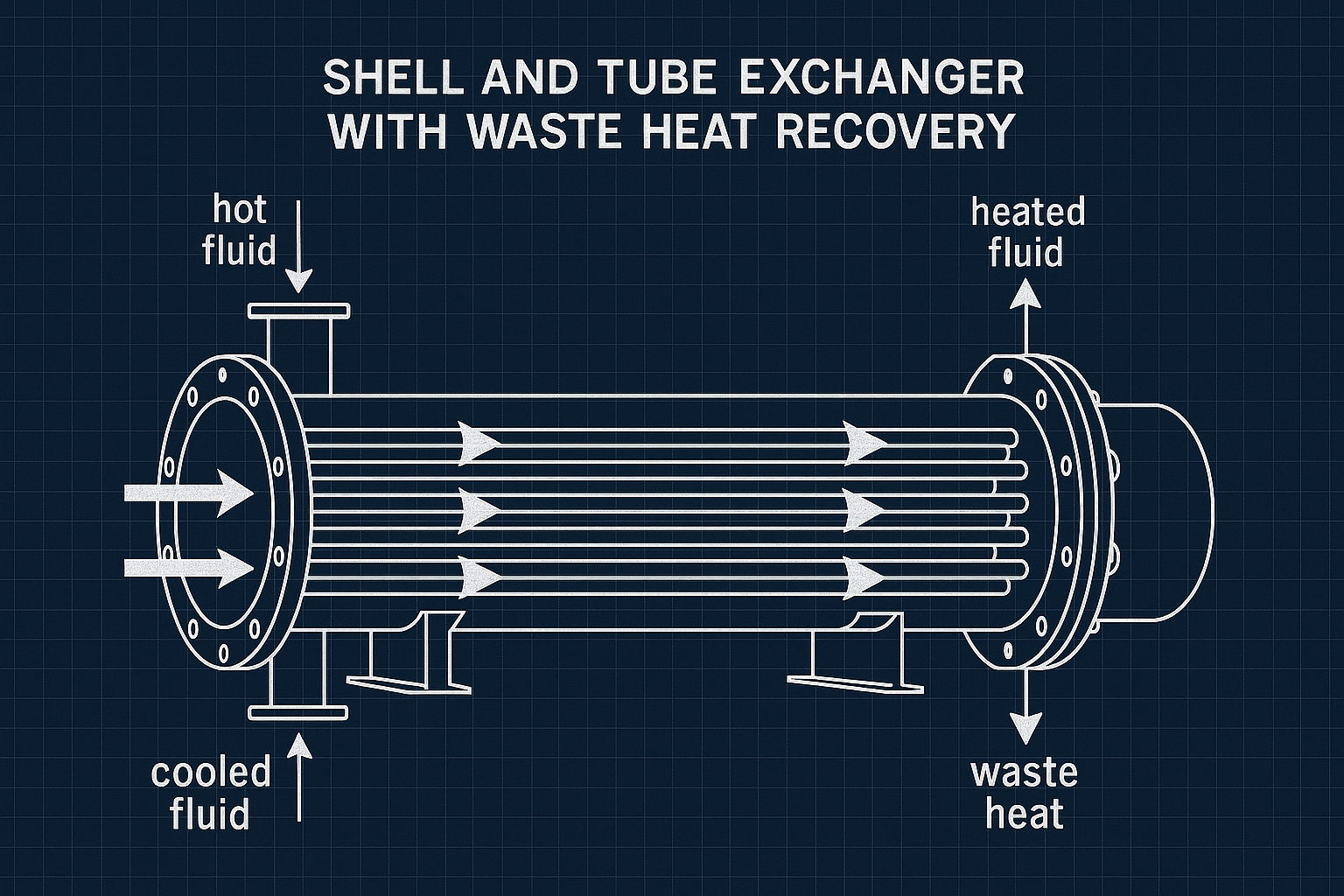

5. Recover Waste Heat

Waste heat recovery boosts efficiency. SHENSHI’s shell and tube exchangers, used in green electricity and CO₂ power generation, reclaim energy from exhaust streams, supporting sustainability.

- Action: Install heat recovery systems.

- Benefit: Reduces energy costs.

Advanced Techniques for Long-Term Efficiency

Monitoring Performance

Real-time monitoring detects issues early. SHENSHI’s ERP and MES systems track exchanger performance, ensuring timely interventions. This approach supports our global service network.

- Tool: Use temperature sensors.

- Outcome: Early problem detection.

Retrofitting Existing Systems

Upgrading older exchangers improves efficiency. SHENSHI offers retrofitting services, leveraging our microchannel expertise from the 2020 CNOOC Gas project.

- Option: Add finned tubes.

- Result: Enhanced heat transfer.

Common Challenges and Solutions

| Challenge | Solution | SHENSHI Support |

|---|---|---|

| Fouling buildup | Regular cleaning schedules | Fouling-resistant PCHE designs |

| Corrosion | Use corrosion-resistant materials | Custom material selection |

| Inefficient flow | Optimize design layout | CFD-optimized exchanger systems |

SHENSHI’s Role in Efficiency

Founded in 2005, SHENSHI Technology leads in shell and tube exchanger innovation. Our products, including coaxial and PCHE designs, serve HVAC, marine, and microchemical industries. With 500+ employees and 46 invention patents, we deliver reliable solutions. In 2024, we supplied 6 compressor aftercoolers for China’s Dongfang 13-2CEPB platform. Explore our offerings at https://en.shenshiec.com/.

Success Stories

- Marine & Offshore: Optimized cooling for offshore platforms.

- Green Electricity: Enhanced efficiency in CO₂ power systems.

Practical Implementation Guide

Step-by-Step Process

- Assess Current Performance: Measure heat transfer rates.

- Identify Issues: Check for fouling or leaks.

- Apply Tips: Optimize flow and clean regularly.

- Upgrade: Consider material or retrofitting options.

- Monitor: Use sensors for ongoing tracking.

Tools and Resources

- SHENSHI’s product manuals (download at Here).

- Industry standards like TEMA.

Conclusion

Boosting shell and tube exchanger efficiency saves energy and costs. SHENSHI Technology combines expertise with sustainable innovation to support your needs. From fouling prevention to waste heat recovery, our solutions drive performance. Visit https://en.shenshiec.com/ to learn more or contact our team for customized support. Let’s build a greener future together.