What is a Marine Coaxial Heat Exchanger and How It Works?

What Is a Marine Coaxial Heat Exchanger?

A marine coaxial heat exchanger is a specialized, high-efficiency component designed for marine HVAC systems, ensuring optimal temperature regulation in harsh marine environments. At Hangzhou Shenshi Energy Conservation Technology Co., Ltd., we leverage nearly 20 years of expertise to deliver compact, energy-efficient, and corrosion-resistant coaxial heat exchangers tailored for marine applications. This section explains what a marine coaxial heat exchanger is, how it works, and why it’s the ideal choice for marine HVAC systems.

Definition and Design

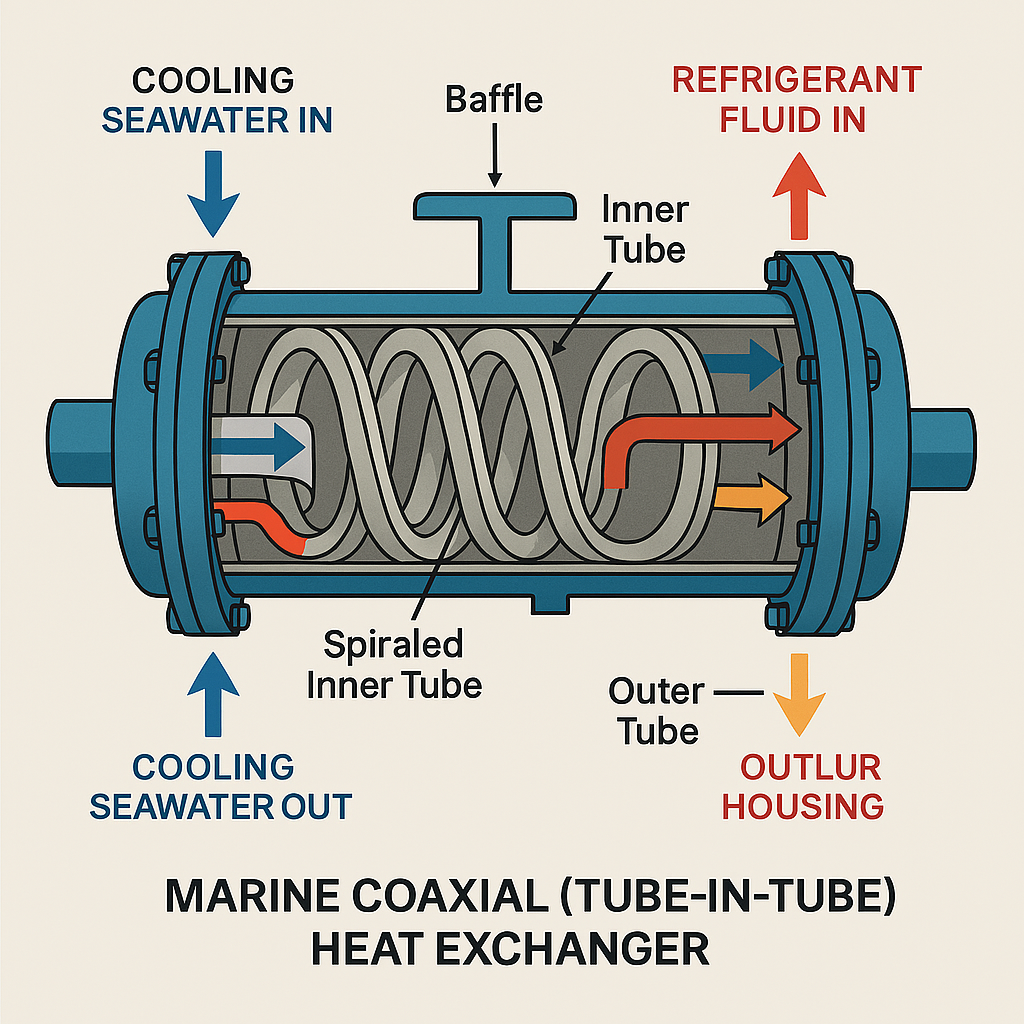

A marine coaxial heat exchanger is a “tube-in-tube” heat exchanger used as a condenser or evaporator in marine HVAC and refrigeration systems. Its compact design consists of an inner tube (typically made of titanium or copper-nickel for corrosion resistance) nested within an outer tube (often steel or copper). The inner tube features spiral grooves to enhance heat transfer efficiency, making it ideal for marine environments where seawater exposure demands durability.

Key Features of Shenshi’s Marine Coaxial Heat Exchangers

- Corrosion Resistance: Built with titanium or copper-nickel to withstand seawater corrosion, ensuring longevity in marine applications.

- Compact Design: Space-saving “tube-in-tube” structure fits seamlessly into vessels with limited space.

- High Efficiency: Spiral grooved inner tubes create turbulence, boosting heat transfer and reducing scaling.

- Versatility: Available in multiple configurations (round, trombone, double helix) to suit various marine HVAC needs.

Our coaxial heat exchangers are designed to meet the rigorous demands of marine environments, ensuring reliable performance for vessels of all sizes.

How Does a Marine Coaxial Heat Exchanger Work?

The marine coaxial heat exchanger operates on the counterflow principle, where two fluids (typically water and refrigerant) flow in opposite directions to maximize heat transfer efficiency. Here’s a step-by-step breakdown of the process:

- Water Flow: Seawater or fresh water flows through the inner tube, which is often made of titanium to resist corrosion in marine environments.

- Refrigerant Flow: The refrigerant (e.g., R410A or R134a) flows between the inner and outer tubes in the opposite direction, creating a counterflow.

- Heat Transfer: Heat is transferred from the warmer fluid (e.g., water) to the cooler fluid (e.g., refrigerant) based on temperature differences. The spiral grooves in the inner tube create turbulence, enhancing heat exchange efficiency and minimizing fouling.

- Cycle Integration: In marine HVAC systems, the cooled water is circulated to cool the vessel’s interior, while the heated refrigerant is compressed and dissipated through a condenser (e.g., via a fan in air-cooled systems).

- Output: The exchanger produces chilled water for air conditioning or absorbs heat for heating, ensuring precise temperature control.

Applications in Marine HVAC Systems

Marine coaxial heat exchangers are critical components in marine HVAC systems, providing reliable cooling and heating for:

- Yachts and Recreational Boats: Compact designs fit small vessels, delivering efficient climate control.

- Commercial Vessels: High-capacity exchangers (1-20 TR) support large-scale cooling for cargo ships and passenger liners.

- Offshore Platforms: Durable materials like titanium ensure performance in harsh saltwater environments.

- Marine Refrigeration: Used in chillers to maintain cold chain systems for perishable goods.

At Shenshi, our coaxial heat exchangers are engineered to meet the unique demands of marine environments, with certifications like ISO9001 and ASME ensuring quality and reliability.

Why Choose Shenshi’s Marine Coaxial Heat Exchangers?

With nearly two decades of expertise, Hangzhou Shenshi Energy Conservation Technology Co., Ltd. is a trusted leader in heat exchanger manufacturing. Our marine coaxial heat exchangers offer:

- Energy Efficiency: Optimized designs reduce energy consumption, aligning with sustainability goals like China’s “dual carbon” strategy.

- Customization: Tailored configurations (e.g., round, spiral, double helix) to meet specific vessel requirements.

- Comprehensive Support: One-year warranty with free replacement for quality issues, plus expert guidance on installation, operation, and maintenance.

- Product Upgrades: We enhance existing systems with cutting-edge technology to improve efficiency and extend lifespan.

Benefits of Marine Coaxial Heat Exchangers

- Durability: Titanium and copper-nickel materials resist corrosion, ensuring long-term performance in seawater.

- Compact Size: Ideal for space-constrained marine vessels, maximizing efficiency without sacrificing space.

- Low Maintenance: Anti-fouling designs reduce scaling, minimizing downtime and maintenance costs.

- High Thermal Efficiency: Counterflow and grooved tubes deliver superior heat transfer, reducing energy costs.

Maintenance Tips for Optimal Performance

To ensure your marine coaxial heat exchanger operates efficiently, follow these tips from Shenshi’s experts:

- Regular Cleaning: Remove scaling with approved descaling agents to maintain heat transfer efficiency.

- Inspect for Corrosion: Check titanium or copper-nickel tubes for signs of wear, especially in seawater applications.

- Monitor Flow Rates: Ensure proper water and refrigerant flow to prevent pressure drops.

- Schedule Maintenance: Partner with Shenshi for professional maintenance services to extend equipment lifespan.

Download our Coaxial Heat Exchanger Product Brochure for detailed specifications and technical data.

Contact Shenshi for Your Marine HVAC Solutions

Ready to enhance your marine HVAC system with a high-efficiency coaxial heat exchanger? At Hangzhou Shenshi, we offer customized solutions backed by 46 patents and nearly 20 years of industry experience. Contact us today for a consultation or to request a quote.